Resources & Solutions

Product Manager

- Phone:+86 (0)21 6536 5235

- Contact: Send E-Mail

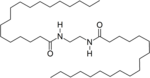

Ethylenebisstearamide

| Structure |  |

|---|---|

| Formula | C38H76N2O2 |

| CAS No. | 68390-94-3; 110-30-5 |

| EC No. | 203-755-6 |

| Synonyms | Ethylene distearamide; EBS; 1,2-Bis(octadecanamido)ethane; Ethylenebisoctadecanamide; Ethylenebis(stearylamide); Ethylenediamine; bisstearamide; N-[2-(octadecanoylamino)ethyl]octadecanamide; N-(2-stearamidoethyl)stearamide;N,N'-1,2-Ethanediylbisoctadecanamide; N,N'-ethane-1,2-diyldioctadecanamide; N,N'-Ethylenebisstearamide; N,N'-Ethylenedistearamide; n,n'-Ethylene distearylamide; Octadecanamide, N,N'-1,2-ethanediylbis-,Octadecanamide, N,N'-ethylenebis-, Octadecanamide, N,N'-ethylenebis-, Stearic acid: Ethylenediamine diamide;110-30-5; |

Ethylenebisstearamide (EBS) is a highly versatile amide wax with widespread applications across various industries. Renowned for its exceptional lubricating properties, EBS functions as both an internal and external lubricant, mold release agent, dispersant, and slip- and anti-blocking agent in the plastics industry, notably in materials like ABS, PS, PP, and more.

As an additive, Ethylenebisstearamide can be seamlessly integrated into polymers to prevent undesired adhesion, especially under elevated temperatures and pressures. It plays a pivotal role in inhibiting the sticking of adhesive granules during storage and preventing the attraction of dirt or cohesion of adhesive film layers before application. Additionally, EBS serves as a process aid, enhancing the dispersion of fillers in polymer matrices.

Beyond the realm of plastics, EBS finds utility as a binder in precision engineering for metal parts. Its excellent dispersing ability and surface migration make it valuable in the formulation of printing inks, contributing to improved ink properties.

In the bitumen industry, EBS plays a crucial role as an asphalt modifier. When incorporated into asphalt binders for road construction, it elevates the softening point and enhances visco-elasticity, contributing to the overall durability and performance of the asphalt mixture.

- Lubricant in Polymer Processing: EBS serves as a highly effective lubricant in the processing of various polymers such as ABS, AS, hard PVC, polyformaldehyde, polycarbonate, polyurethane, and phenol-formaldehyde resins. It exhibits excellent inner and outer lubrication properties and works synergistically with other lubricants like high-grade alcohols, aliphatic acid esters, calcium stearate, and paraffin. Used as a demoulding agent, EBS enhances coordination in the processing, typically at a recommended quantity of 0.5~1.5%.

- Anti-Adhesive Agent for Polymer Films: EBS finds application as an anti-adhesive agent for polymer films and sheets. When added at 0.5-1%, it not only prevents the formation of air bubbles but also imparts slipperiness to plastic bags, facilitating easy opening.

- Enhancer of Heat-Resistant and Weather-Resistant Properties: EBS significantly improves the heat-resistant and weather-resistant properties of polymers, especially when formulated with inorganic fillers for PVC and polyolefins. Its strong cohesion with pigments and fillers enhances dispersion and coupling properties, thereby increasing the commercial value of products.

- Nucleation Transparency Agent: In compounds like polyolefins, polyformaldehyde, and polyamide, EBS acts as a nucleation transparency agent. It reduces nucleating time, refines the resin structure, and enhances mechanical properties and transparency of the end products.

- Enhancer in Synthetic Fiber Industry: EBS enhances the heat-resistant and weather-resistant properties of polyester and polyamide in the synthetic fiber industry. It is employed as an additive in antistatic nylon fiber spinning, reducing yarn breakage.

- Processing Auxiliary in Rubber Industry: EBS serves as a processing auxiliary in the rubber industry, improving the lubricant demoulding property and modifying the performance of filler surfaces. It enhances the surface fineness of rubber pipes and plates, acting as a rubber surface polishing agent.

- Coating Additive for Improved Properties: When added to coatings, EBS enhances the dispersion of pigments and fillers, improves surface leveling properties, prevents paint film stripping, and enhances water, acid, and alkali resistance. In nitrocellulose lacquers, it provides a flatting action.

- Lubricant in Powder Metallurgy (PM): In powder metallurgy, EBS acts as a lubricant in PM steels, reducing inter-particle and die-wall friction during pressing. This improves powder compressibility and the ejection of components from compaction tools.

- Paper-Making Industry: EBS serves as a defoamer/anti-foaming agent and coating component in the paper-making industry.

- Dope and Oil Paint Additive: In the manufacturing process of dope and oil paint, EBS enhances salt mist and damp-proof effects, improves paint remover performance, and serves as a dulling agent for polishing furniture and printing ink. Its excellent wearable and smoothing properties make it suitable for improving lacquer polishing performance and air release on surfaces with holes.

Under proper storage conditions, the shelf life is 36 months

For more details and safety recommendations regarding the use of the product, please consult our Material Safety Data Sheet (MSDS), or Contact With our Product Manager.