Exploring the Chemistry and Applications of 2,2′- (Ethylenedioxy) Dianiline (CAS No. 52411-34-4)

2,2′- (Ethylenedioxy) Dianiline (CAS No. 52411-34-4) is a versatile chemical compound extensively employed as a cross-linking agent in the production of polyimide fibers, films, and slurries. This application significantly enhances the thermal and mechanical characteristics of polyimide materials, crucial for a wide range of high-performance uses. Furthermore, it plays a pivotal role as a key intermediate in the synthesis of Pigment Yellow 180, a widely utilized colorant across various industries. The distinctive chemical structure of 2,2′- (Ethylenedioxy) Dianiline, featuring an ethylenedioxy bridge linking two aniline groups, confers specific reactivity and properties that are indispensable for tailored manufacturing processes, available through suppliers like UniVOOK Chemical.

Use of 2,2′- (Ethylenedioxy) Dianiline in Industrial Applications

Role in Polyimide Fiber Production

2,2′- (Ethylenedioxy) Dianiline plays a crucial role as a cross-linking agent in the production of polyimide fibers. By facilitating the formation of cross-links between polymer chains, it enhances the structural integrity of polyimide fibers. This enhancement is vital for applications in aerospace and electronics, where the fibers must withstand high temperatures and mechanical stresses.

Enhancing Thermal and Mechanical Properties of Polyimide Films

In polyimide films, 2,2′- (Ethylenedioxy) Dianiline significantly improves thermal stability and mechanical strength. These properties are essential in the electronics industry, where polyimide films are used for flexible printed circuits and insulation materials. The compound’s ability to enhance these properties ensures that polyimide films maintain performance under extreme environmental conditions.

Use in Formulating Polyimide Slurries

2,2′- (Ethylenedioxy) Dianiline is also utilized in the formulation of polyimide slurries, which find applications in coatings and composite materials. By improving adhesion and thermal properties, the compound enhances the durability and performance of polyimide-based products used in automotive and aerospace components.

Role as an Intermediate for Pigment Yellow 180

Function in Pigment Synthesis

As a key intermediate, 2,2′- (Ethylenedioxy) Dianiline plays a pivotal role in the synthesis of Pigment Yellow 180. It actively participates in chemical reactions that lead to the formation of this pigment, known for its vibrant yellow color and excellent lightfastness. This makes Pigment Yellow 180 suitable for high-quality coatings and plastics.

Importance in Pigment Yellow 180 Production

The chemical properties of 2,2′- (Ethylenedioxy) Dianiline ensure consistent quality and color intensity in Pigment Yellow 180 production. This pigment is extensively used in the paint and automotive industries to achieve durable and visually appealing finishes.

Industrial Applications of Pigment Yellow 180

Pigment Yellow 180 finds widespread applications across various industries, including plastics, paints, and inks. Its superior resistance to fading under sunlight and environmental conditions makes it a preferred choice for outdoor applications, ensuring longevity and aesthetic appeal in products.

Chemical Properties of 2,2′- (Ethylenedioxy) Dianiline

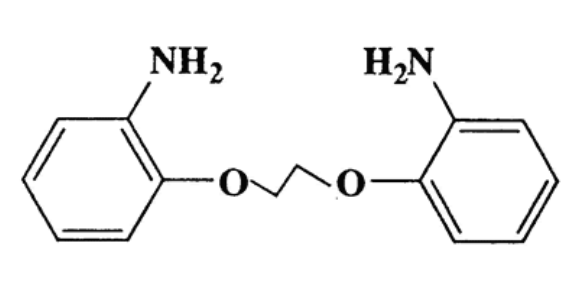

Molecular Structure and Reactivity

2,2′- (Ethylenedioxy) Dianiline is characterized by a unique molecular structure featuring an ethylenedioxy bridge that links two aniline moieties. This structure imparts high reactivity, enabling the compound to participate effectively in polymerization and dye synthesis reactions.

Stability and Solubility

The compound exhibits excellent thermal stability and chemical resistance, essential for its applications in high-performance materials. It is moderately soluble in organic solvents, facilitating its use in organic synthesis and various industrial processes. These stability and solubility characteristics are crucial for effective handling and processing in chemical manufacturing settings.

Industrial Applications Beyond Polyimide and Pigment Production

Versatility Across Diverse Sectors

2,2′- (Ethylenedioxy) Dianiline plays a pivotal role in various industrial sectors beyond its conventional applications in polyimide fiber and Pigment Yellow 180 production. In the electronics industry, it enhances thermal stability and adhesion properties in coatings and adhesives crucial for high-performance electronic components. Its inclusion in specialty polymers strengthens automotive parts, improving durability under demanding conditions. Additionally, the compound contributes to the formulation of specialty films and membranes known for their chemical resistance and robust performance in harsh environments.

Broad Usage Examples

Across industries, 2,2′- (Ethylenedioxy) Dianiline is integral to advanced composite materials in aerospace, reinforcing structures against extreme temperatures and mechanical stresses. It also aids in specialty adhesives vital for assembling electronic devices. Moreover, its role extends into pharmaceuticals, facilitating the synthesis of specialty chemicals and pharmaceutical intermediates. These applications highlight its diverse utility beyond traditional roles, demonstrating its importance in enhancing product performance across various industrial domains.

Safety and Handling Considerations

Ensuring Safe Handling Practices

Due to its hazardous nature, strict safety protocols are essential when handling 2,2′- (Ethylenedioxy) Dianiline to mitigate potential health risks. The compound can cause skin and eye irritation upon contact, necessitating the use of personal protective equipment (PPE) such as gloves, goggles, and lab coats. Adequate ventilation and containment measures are critical to minimize exposure to vapors and prevent accidental spills during handling and processing. Comprehensive training on safe handling practices and emergency procedures is imperative for personnel to ensure safe operations in industrial settings.

Environmental Impact and Regulatory Compliance

2,2′- (Ethylenedioxy) Dianiline presents environmental challenges, primarily concerning bioaccumulation and persistence in aquatic ecosystems. To mitigate environmental impact, effective waste management practices, including recycling and proper treatment of contaminated materials, should be implemented. Regulatory bodies such as the Environmental Protection Agency (EPA) enforce stringent guidelines on the handling, storage, and disposal of 2,2′- (Ethylenedioxy) Dianiline to safeguard environmental and human health. Compliance with these regulations is crucial for industrial facilities and chemical manufacturers to uphold sustainable practices throughout the compound’s lifecycle and ensure minimal environmental footprint.

In Sum

To summarize, 2,2′- (Ethylenedioxy) Dianiline is a versatile chemical compound widely applied across electronics, aerospace, automotive, and pharmaceutical industries. Its role as both a cross-linking agent in polyimide products and an intermediate in pigment production is essential for enhancing material performance and durability. The unique chemical properties of 2,2′- (Ethylenedioxy) Dianiline improve mechanical and thermal characteristics, driving innovation in industrial applications. However, its hazardous nature mandates stringent safety measures during handling, while environmental considerations require careful management and regulatory adherence. Looking ahead, ongoing research and application of 2,2′- (Ethylenedioxy) Dianiline promise significant advancements in material sciences and manufacturing, emphasizing safety and environmental responsibility.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs