4-(Ethoxyethoxy)Styrene: A Polymeric Chain Extender for Enhanced Polymerization and Material Properties

Chain extenders help improve the properties of polymers, making them stronger and more durable. One promising chain extender is 4-(Ethoxyethoxy)Styrene (EEStyrene). EEStyrene has shown great potential in enhancing polymerization processes and the resulting material properties. This study aims to explore how EEStyrene affects polymerization and the characteristics of the final materials. UniVOOK Chemical includes EEStyrene in its range of products. The company manufactures and distributes various industrial and electronic-grade styrene derivatives. UniVOOK Chemical has a total production capacity of 6,000 metric tons. This capacity ensures a steady supply of high-quality styrene derivatives for different industrial applications.

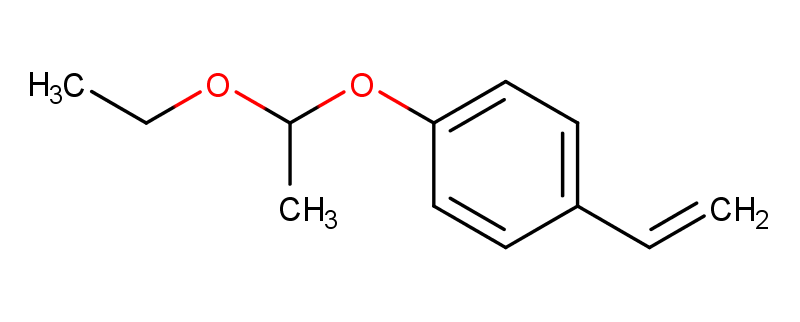

Chemical Structure and Synthesis of 4-(Ethoxyethoxy)Styrene

Structural Properties of 4-(Ethoxyethoxy)Styrene

4-(Ethoxyethoxy)Styrene (EEStyrene) possesses a unique chemical structure that makes it an effective chain extender. The molecule features a styrene backbone with two ethoxy groups connected by an ether linkage, which imparts flexibility to the structure. These ether groups enable EEStyrene to interact effectively with polymer chains, enhancing their properties. Furthermore, the styrene segment of the molecule contains a vinyl group, crucial for initiating the polymerization process. This structure allows EEStyrene to link polymer chains, resulting in increased molecular weight and enhanced strength and durability of the material.

Synthesis Methods for EES

EEStyrene is synthesized through a simple chemical reaction, beginning with the reaction of styrene and ethylene oxide. Ethylene oxide, a highly reactive compound, forms ethoxy groups upon reaction with styrene. The ethoxy groups attach to the styrene backbone, forming EEStyrene. This reaction is typically catalyzed to accelerate the process, with temperature and pressure carefully controlled to optimize yield. Following the reaction, purification steps remove any unreacted materials or by-products, ensuring a pure product. The synthesis method is efficient and scalable, making large-scale industrial production feasible.

Discussion on Purity, Stability, and Scalability of Production

The purity of EEStyrene is essential for its role as a chain extender, as impurities can interfere with polymerization. Multiple purification steps are employed to ensure high purity, removing any residual reactants and by-products. Stability is another critical factor, as EEStyrene must withstand various conditions during its application. EEStyrene demonstrates excellent thermal stability, making it suitable for polymers requiring heat resistance. Scalability is also a key consideration, with the synthesis method designed for large-scale production without compromising purity or stability. UniVOOK Chemical has refined this process to maintain high standards of purity and stability even in larger quantities.

Role of 4-(Ethoxyethoxy)Styrene as a Chain Extender

Mechanism of Action as a Chain Extender in Polymerization

EEStyrene functions as a chain extender by linking polymer chains during the polymerization process. Its vinyl groups react with growing polymer chains, forming cross-links that extend the chains and increase molecular weight. This results in polymers with improved mechanical properties, such as increased strength and toughness. The ether groups in EEStyrene also enhance polymer flexibility, reducing brittleness and improving durability, which is crucial for many applications.

Comparison with Other Chain Extenders

EEStyrene has several advantages over other chain extenders. It reacts quickly during polymerization, helping maintain high polymerization rates, which enhances efficiency and reduces costs. It is also more effective at increasing polymer molecular weight, meaning smaller quantities are needed to achieve the desired properties. Additionally, EEStyrene imparts better flexibility to polymers compared to some other extenders, leading to materials that are stronger and more resistant to cracking. Overall, EEStyrene combines high effectiveness with efficient polymerization, making it a cost-effective and versatile option.

Impact on Polymerization Kinetics

How EES Influences Polymer Chain Growth

EEStyrene significantly impacts the growth of polymer chains by incorporating its vinyl groups into the growing polymer chains. This incorporation leads to the formation of cross-links between different chains, resulting in longer and more interconnected chains. The increased molecular weight enhances the polymer’s mechanical properties, such as tensile strength and elasticity. Moreover, EEStyrene can regulate the rate of polymer chain growth, contributing to a more uniform polymer structure.

Effects on Polymer Molecular Weight Distribution

The addition of EEStyrene broadens the molecular weight distribution of the polymer, creating a wider range of molecular weights in the sample. A broader distribution can improve properties like toughness and impact resistance. However, care must be taken to optimize EEStyrene concentration to avoid excessive cross-linking, which can increase rigidity and reduce flexibility. Properly controlling the amount of EEStyrene added ensures an ideal balance of molecular weight distribution and material properties.

Effects on Mechanical Properties During Polymerization

EEStyrene positively impacts the mechanical properties of the polymer during polymerization. By increasing the molecular weight and introducing cross-links, it improves the polymer’s strength, durability, and elasticity. These enhancements make the material more resistant to impact, deformation, and cracking. As a result, polymers containing EEStyrene are more robust and reliable for various demanding applications.

Enhanced Material Properties

Effects on Polymer Toughness, Flexibility, and Strength

EEStyrene enhances polymer toughness, flexibility, and strength. By increasing the molecular weight and introducing cross-links, EEStyrene improves the material’s ability to absorb energy and resist fracture. The ether groups in EEStyrene provide flexibility to the polymer chains, preventing the material from becoming overly rigid or brittle. Additionally, the increased molecular weight contributes to higher tensile strength. Together, these improvements lead to more durable materials suitable for a range of industrial applications.

Impact on Glass Transition Temperature (Tg), Crystallinity, and Elasticity

EEStyrene can lower the glass transition temperature (Tg) of polymers, making them more flexible at lower temperatures. It also influences the crystallinity of polymers by reducing structural order, which increases the material’s amorphousness. This reduction in crystallinity enhances elasticity, allowing the polymer to stretch and return to its original shape. These changes in Tg, crystallinity, and elasticity improve the material’s performance across a variety of conditions.

Examples of Materials Enhanced by EES

EEStyrene has been used to enhance a wide range of materials, including polystyrene and acrylics. In polystyrene, EEStyrene improves toughness and impact resistance, making it ideal for packaging and insulation. In acrylics, EEStyrene enhances flexibility and strength, which benefits applications in coatings and adhesives. Additionally, EEStyrene has been successfully incorporated into other systems, such as polyurethane and epoxy resins, to improve their mechanical properties. These examples highlight EEStyrene’s versatility in enhancing a broad spectrum of polymer systems.

Applications and Future Perspectives

Potential Industrial Applications

EEStyrene offers a broad range of industrial applications due to its ability to enhance polymer properties. In coatings, it improves durability and resistance to cracking, extending the lifespan of the coating. In adhesives, EEStyrene increases strength and flexibility, resulting in stronger and more reliable bonds. The plastics industry benefits from EEStyrene by producing more durable and flexible materials for use in packaging, automotive parts, and various other applications. EEStyrene is also valuable in electronics, where improved material properties are critical for performance and longevity.

Long-term Stability and Environmental Factors

The long-term stability of EEStyrene-enhanced polymers is vital for their practical use. These polymers demonstrate good resistance to environmental factors such as temperature fluctuations, UV exposure, and moisture, ensuring they maintain their properties over time. EEStyrene also enhances chemical stability, reducing the risk of material degradation. However, further research is needed to fully understand the long-term performance of EEStyrene in various environmental conditions and to optimize its use in extreme conditions.

Future Research Directions and Optimization of EES for Specific Polymer Systems

Future research on EEStyrene will focus on optimizing its use in specific polymer systems to achieve superior performance. Studies will explore new synthesis methods to improve purity, scalability, and production efficiency. Additionally, research will examine how EEStyrene interacts with different polymers to tailor properties for specific applications. By refining its concentration in polymer mixtures, researchers can further enhance material properties such as flexibility and strength. Moreover, future studies may explore the environmental impact of EEStyrene and develop more sustainable production techniques. With continued optimization, EEStyrene’s full potential can be realized, expanding its range of applications in the polymer industry.

Final Thoughts

In this study, we investigated the use of 4-(Ethoxyethoxy)Styrene (EEStyrene) as a chain extender in polymer systems. EEStyrene efficiently connects polymer chains, enhancing both their strength and flexibility. It outperforms other chain extenders by accelerating polymerization rates and improving material properties. The increased toughness and stability provided by EEStyrene make it highly suitable for a range of industrial applications. Future work will aim to refine its use and broaden its potential applications. Overall, EEStyrene holds significant promise for advancing polymer science and developing superior materials.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs