Why 4-Tert-Butoxystyrene is Gaining Popularity in Chemical Synthesis

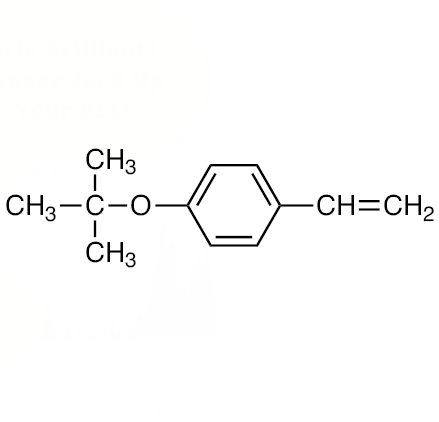

Can a single compound, with just a few modifications at the structural level, significantly impact and transform both polymer chemistry and a variety of industrial applications? Consider 4-Tert-Butoxystyrene—a multifaceted styrene derivative that, due to its distinctive chemical properties and expansive range of applications, is being increasingly adopted across various domains. Characterized by a molecular weight of 176.26 and boasting a remarkable purity level of 99% or greater, this compound, also known as PTBS, is emerging as a highly desirable monomer in the realm of advanced chemical synthesis. But what, precisely, is driving this surge in interest and adoption?

Applications of 4-Tert-Butoxystyrene: Spanning from Synthesis to End-Product Development

An Integral Intermediate in Ion Exchange Resins and Photoresist Polymers

One of the central reasons behind 4-Tert-Butoxystyrene’s rising prominence within the chemical industry can be attributed to its critical function as an intermediate in the creation of ion exchange resins and photoresist polymers. Ion exchange resins play an indispensable role in water treatment processes and various environmental applications, whereas photoresist polymers are indispensable within the semiconductor sector, where they are utilized extensively in the fabrication of microelectronic devices. Due to its outstanding compatibility and reactive nature, 4-Tert-Butoxystyrene guarantees high performance and reliability within these sophisticated, high-tech applications.

Moreover, 4-Tert-Butoxystyrene is employed in the production of crosslinked fibers and coupling agents that are crucial in the formulation of advanced materials. These fibers and coupling agents deliver enhanced durability, flexibility, and chemical resistance, making them suitable for deployment in demanding industrial environments, including those exposed to harsh chemical and physical conditions.

Improving the Characteristics of Conductive Polymers and Pharmaceutical Products

Apart from its applications in resins and fibers, 4-Tert-Butoxystyrene also serves as a valuable component in the synthesis of conductive polymers. Conductive polymers, known for their electrical conductivity, are integral to a multitude of applications such as flexible electronics, high-sensitivity sensors, and energy storage systems. The distinctive chemical structure of 4-Tert-Butoxystyrene contributes significantly to the enhancement of electrical performance and thermal stability within these polymers, thereby expanding the possibilities in the field of materials science.

The pharmaceutical sector has also found substantial utility in 4-Tert-Butoxystyrene. Acting as a bifunctional styrene monomer, it proves to be an effective intermediate for synthesizing complex organic molecules. Its high purity and exceptional reactivity afford precise control over the chemical synthesis process, which is critical for producing top-tier pharmaceutical products with stringent quality requirements.

Catalyzing Innovation within the Polymer Science Sector

UniVOOK Chemical, a foremost producer of 4-Tert-Butoxystyrene, stands at the vanguard of this innovation. By providing both industrial-grade and electronic-grade 4-Tert-Butoxystyrene, UniVOOK Chemical is enabling the development of new materials and technologies that are poised to redefine the future of polymer science. Their substantial production capacity, amounting to 6000 metric tons, ensures a steady supply of high-quality styrene derivatives, empowering researchers and manufacturers to explore new horizons in chemical innovation.

Polymerization of 4-Tert-Butoxystyrene: Approaches, Considerations, and Best Practices

Optimal Polymerization Methods for 4-Tert-Butoxystyrene

Several polymerization methods are applicable for 4-Tert-Butoxystyrene, including free-radical polymerization, anionic polymerization, and controlled/living polymerization. Each technique offers unique benefits based on the specific attributes desired in the final polymer product. For example, free-radical polymerization is relatively simple and cost-effective, making it a preferred method for large-scale manufacturing. In contrast, anionic polymerization enables more precise control over molecular weight distribution and polymer structure, rendering it ideal for high-performance applications.

A key best practice for successful polymerization is maintaining a monomer purity level exceeding 99%, as any impurities can trigger unwanted side reactions, ultimately compromising the quality and functionality of the final polymer. Furthermore, meticulous control of temperature and initiator concentration during polymerization is essential to achieve the target molecular weight and structural features.

Copolymerization: Merging 4-Tert-Butoxystyrene with Other Styrene Derivatives

4-Tert-Butoxystyrene is also amenable to copolymerization with other styrene derivatives, resulting in copolymers with bespoke properties. Through this copolymerization process, functional groups can be incorporated to bolster the mechanical, thermal, and chemical resistance properties of the resulting materials. As a bifunctional monomer, 4-Tert-Butoxystyrene is particularly well-suited for creating copolymers that exhibit superior performance even in the most demanding of applications.

When implementing copolymerization, it is crucial to judiciously select comonomers and fine-tune reaction conditions. Maintaining a balanced ratio between monomers can yield copolymers with outstanding uniformity and the desired characteristics, which is vital for ensuring consistency and reliability in industrial applications.

Transitioning from Laboratory-Scale to Industrial-Scale Production

Scaling up the polymerization process for 4-Tert-Butoxystyrene—from a small-scale laboratory environment to full-scale industrial production—introduces an array of challenges. Elements such as reaction kinetics, heat dissipation, and mixing efficiency must be carefully managed to maintain the desired quality and uniformity of the final product. UniVOOK Chemical’s profound expertise in scaling chemical processes ensures that their industrial-grade 4-Tert-Butoxystyrene adheres to strict quality standards, making it apt for high-volume applications across various sectors.

From Laboratory Bench to Commercial Market: The Transformative Potential of 4-Tert-Butoxystyrene in the Polymer Industry

Facilitating the Creation of Advanced Materials

Thanks to its adaptability and unique properties, 4-Tert-Butoxystyrene has emerged as a pivotal element in the polymer industry. Its capability to serve as a monomer, initiator, or copolymer constituent enables researchers and manufacturers to develop a broad array of advanced materials. These materials are being utilized in multiple industries, including electronics, automotive, and healthcare, where they offer enhanced performance and greater reliability.

Ensuring High-Purity Monomers for the Electronics Industry

Within the electronics industry, ensuring product purity is of utmost importance, as even trace impurities can cause defects and compromise the performance of electronic devices. UniVOOK Chemical’s electronic-grade 4-Tert-Butoxystyrene, characterized by a purity of 99% or more, guarantees that manufacturers can produce high-quality photoresist polymers and other essential electronic components with a minimized risk of contamination. This level of quality assurance is crucial for meeting the rigorous standards required in semiconductor and electronics manufacturing.

Addressing Market Demands with Robust Production Capabilities

As demand for innovative materials continues to escalate, so does the necessity for high-quality monomers like 4-Tert-Butoxystyrene. UniVOOK Chemical, with its extensive production capabilities and unwavering commitment to excellence, is well-equipped to fulfill this demand. Their comprehensive product portfolio of styrene derivatives, combined with their advanced technical know-how, ensures they can support diverse industrial needs ranging from chemical synthesis to electronics fabrication.

Anticipating the Future: Emerging Research and Development Trends in 4-Tert-Butoxystyrene

Innovations in Polymerization Techniques

Ongoing research into novel polymerization methods is paving the way for more efficient and sustainable production of 4-Tert-Butoxystyrene-based polymers. Techniques such as reversible deactivation radical polymerization (RDRP) and atom transfer radical polymerization (ATRP) are providing unprecedented control over polymer architecture and functionality, thereby enabling the development of cutting-edge materials with highly specialized properties.

Expanding Horizons with New Applications

The multifaceted nature of 4-Tert-Butoxystyrene is facilitating exploration into new application domains, including nanotechnology, biomedicine, and energy storage. Researchers are investigating its potential in creating nanostructured materials, drug delivery platforms, and high-capacity energy storage systems. As these novel applications continue to mature, 4-Tert-Butoxystyrene is poised to become a critical building block in the development of next-generation technologies.

Embracing Sustainable and Green Chemistry Practices

With sustainability taking center stage in chemical synthesis, 4-Tert-Butoxystyrene is also under scrutiny for the development of greener production methods and more environmentally friendly polymerization processes. By minimizing the environmental impact associated with the production and utilization of 4-Tert-Butoxystyrene, the chemical industry is contributing to a more sustainable future.

Conclusion: UniVOOK Chemical’s Dedication to Quality and Innovation

UniVOOK Chemical’s position as a premier producer of 4-Tert-Butoxystyrene underscores their commitment to quality and innovation. With an extensive portfolio, deep technical expertise, and a steadfast focus on sustainability, UniVOOK Chemical is uniquely positioned to support the evolving needs of the chemical and polymer industries. Be it in developing new materials or optimizing existing processes, UniVOOK Chemical remains at the forefront of driving innovation with 4-Tert-Butoxystyrene, ensuring a brighter, more sustainable future for the industry at large.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs