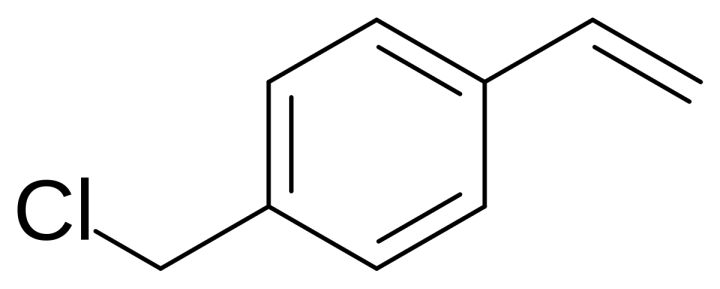

Synthesis and Applications of 4-Vinylbenzyl Chloride in Polymer Chemistry

4-Vinylbenzyl Chloride (4-VBC) is a vital compound in polymer chemistry, playing a significant role in the production of a wide range of materials. Manufactured by UniVOOK Chemical, 4-VBC is primarily used as an intermediate in the synthesis of ion exchange resins. It also serves in the production of photoresist polymers, crosslinked fibers, coupling agents, and conductive polymers. Additionally, 4-VBC functions as an initiator in the polymerization of various copolymers and acts as a bifunctional monomer in organic synthesis. These diverse applications highlight the crucial role 4-VBC plays in the advancement of modern materials science.

Synthesis of 4-Vinylbenzyl Chloride

Description of the Chemical Synthesis of 4-VBC

4-Vinylbenzyl Chloride (4-VBC) is synthesized through a chemical reaction that introduces a chloride group to the vinylbenzyl structure. The process starts with 4-vinylbenzyl alcohol as the base compound. This alcohol undergoes a reaction with a chlorinating agent to replace the hydroxyl group with a chlorine atom. The result is 4-VBC, a valuable intermediate in various chemical processes.

Key Reactions Involved

One of the main reactions in the synthesis of 4-VBC is the chlorination of 4-vinylbenzyl alcohol. This reaction involves adding chlorine to the alcohol to form the chloride. Another important reaction is the elimination reaction, which helps in forming the vinyl group necessary for polymerization. These key reactions ensure the efficient production of high-purity 4-VBC.

Mechanisms of Polymerization

Polymerization of 4-VBC involves linking its molecules to form long chains. The process begins with the initiation step, where free radicals start the reaction. These radicals react with 4-VBC molecules, causing them to connect. The propagation step continues this chain reaction, adding more 4-VBC units. Finally, termination occurs when the reactive chains are stopped, resulting in the formation of the polymer.

Reaction Conditions and Reagents Used

The synthesis of 4-VBC requires specific reaction conditions to ensure success. Typically, the reaction is carried out at moderate temperatures to control the rate of reaction. A chlorinating agent, such as thionyl chloride or phosphorus pentachloride, is used to introduce the chlorine atom. Solvents like dichloromethane may be used to dissolve the reactants and facilitate the reaction. Proper control of these conditions is essential for high yields and purity.

Purification and Isolation Methods

After synthesis, 4-VBC needs to be purified to remove any unreacted materials and by-products. Common purification methods include distillation and recrystallization. Distillation separates 4-VBC based on its boiling point, while recrystallization involves dissolving the compound in a solvent and then cooling it to form pure crystals. These methods ensure that the final product is free from impurities and suitable for further use.

Polymerization of 4-Vinylbenzyl Chloride

Free Radical Polymerization

Free radical polymerization is a common method used to polymerize 4-VBC. In this process, free radicals initiate the reaction by attacking the double bonds in 4-VBC. This leads to the formation of long polymer chains. The method is straightforward and widely used due to its simplicity and effectiveness in producing polymers with desired properties.

Controlled/Living Polymerization Techniques

Controlled or living polymerization techniques offer better control over the polymer structure. These methods allow for the precise regulation of the molecular weight and distribution of the polymer chains. Techniques such as Atom Transfer Radical Polymerization (ATRP) and Reversible Addition-Fragmentation Chain Transfer (RAFT) are used with 4-VBC to achieve polymers with specific characteristics and functionalities.

Copolymerization with Other Monomers

4-VBC can be copolymerized with other monomers to create diverse polymer materials. Copolymerization involves combining 4-VBC with different monomers like styrene or acrylic acid. This process results in polymers that inherit properties from both monomers, enhancing their functionality and applicability in various fields such as coatings, adhesives, and plastics.

Effect of Polymerization Conditions on the Properties of the Resulting Polymer

The conditions under which polymerization is conducted greatly affect the properties of the resulting polymer. Factors like temperature, solvent, and concentration influence the molecular weight and structure of the polymer chains. For example, higher temperatures may lead to faster reactions but can reduce control over the polymer structure. Adjusting these conditions allows for the tailoring of polymer properties to meet specific requirements.

Applications of 4-Vinylbenzyl Chloride in Polymer Chemistry

Development of Functional Polymers

4-VBC is essential in developing functional polymers that perform specific tasks. Its structure allows for the introduction of various functional groups into the polymer chain. These functional polymers can be designed to have properties like increased strength, chemical resistance, or specific reactivity, making them suitable for specialized applications in industries like automotive and electronics.

Surface Modification and Grafting Techniques

Surface modification involves altering the surface properties of materials to enhance their performance. 4-VBC is used in grafting techniques to attach polymer chains to surfaces. This process improves adhesion, durability, and compatibility of materials. For example, grafting polymers onto glass or metal surfaces can enhance their resistance to corrosion and improve their bonding with other materials.

Use in the Preparation of Nanocomposites

Nanocomposites are materials that combine polymers with nanoscale fillers to achieve superior properties. 4-VBC plays a role in the preparation of these nanocomposites by acting as a compatibilizer. It helps in the uniform dispersion of nanoparticles within the polymer matrix, enhancing properties like strength, thermal stability, and electrical conductivity. These nanocomposites are used in applications ranging from aerospace to consumer electronics.

Biomedical and Industrial Applications

4-VBC is used in various biomedical and industrial applications. In the biomedical field, it is involved in creating drug delivery systems that control the release of medications. In industrial settings, 4-VBC is used in coatings that protect surfaces from wear and corrosion. Additionally, it is used in the production of adhesives and sealants that require strong bonding and durability.

Anti-Glass Fiber Exposure Agent

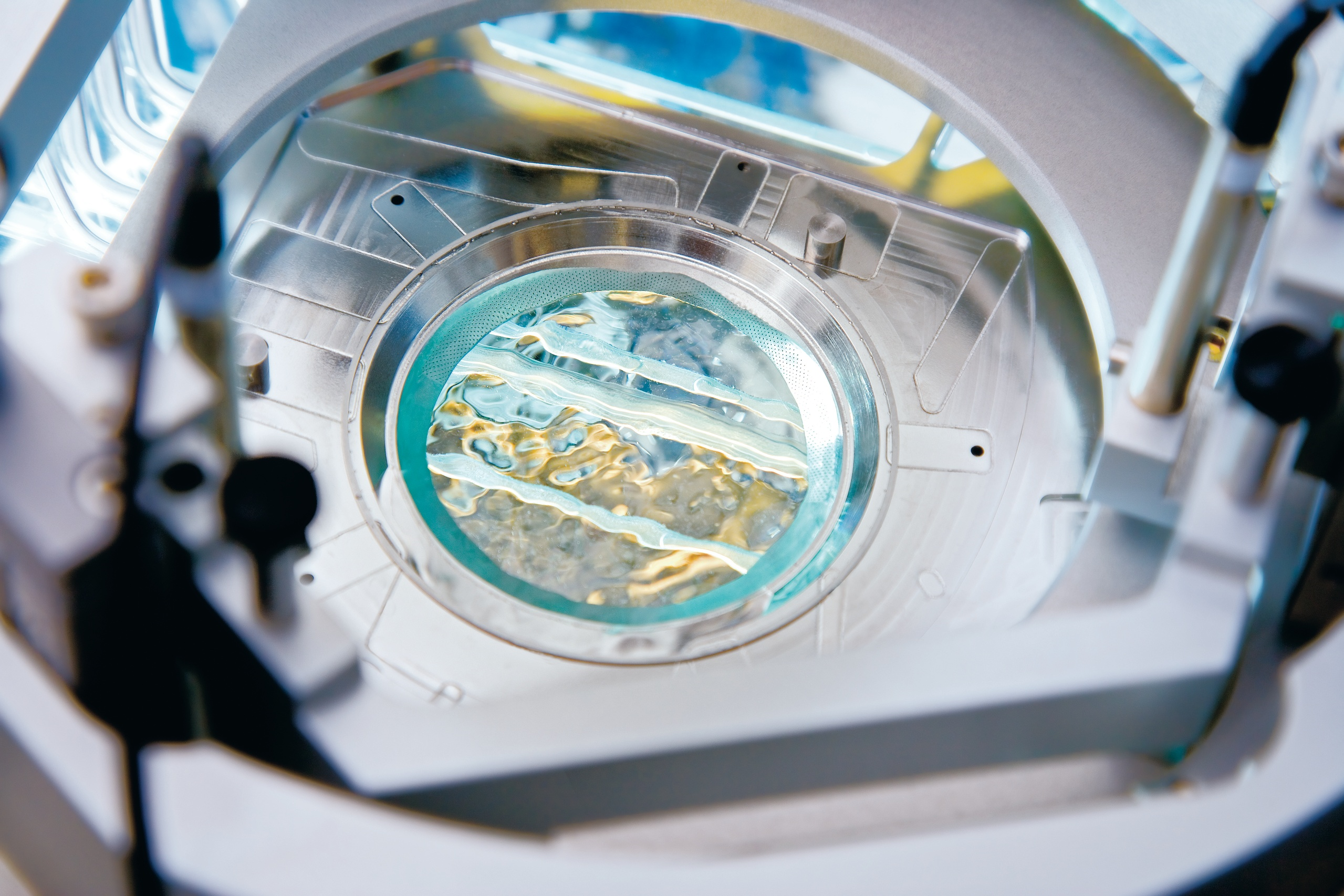

Introduction to Glass Fiber Exposure and Its Challenges

Glass fiber exposure occurs when tiny glass fibers become airborne during the manufacturing or processing of glass fiber-reinforced materials. This exposure poses health risks, such as respiratory issues and skin irritation. Managing glass fiber exposure is crucial to ensure the safety of workers and the quality of the final products. Traditional methods to control exposure have limitations, leading to the need for improved solutions.

Role of 4-Vinylbenzyl Chloride in Developing Anti-Exposure Agents

4-VBC is instrumental in developing anti-glass fiber exposure agents. It acts as a key component in creating agents that prevent glass fibers from becoming airborne. By incorporating 4-VBC into these agents, manufacturers can enhance their effectiveness in binding glass fibers and reducing their release during processing. This leads to safer working environments and higher quality products.

Mechanism of Action

The anti-exposure agents containing 4-VBC work by interacting with both the glass fibers and the resin matrix. The chloride groups in 4-VBC form bonds with the glass fibers, while the vinyl groups react with the resin. This dual action ensures that the glass fibers are well-dispersed and firmly held within the resin, preventing them from detaching and causing exposure.

How 4-VBC Reduces Glass Fiber Exposure Hazards

4-VBC reduces glass fiber exposure hazards by improving the adhesion between glass fibers and the resin. This enhanced adhesion prevents the fibers from breaking loose and becoming airborne. Additionally, 4-VBC helps in evenly distributing the fibers within the resin, further minimizing the chances of fiber release. As a result, products made with these agents exhibit lower levels of fiber exposure.

Applications in Protective Coatings and Materials

Anti-glass fiber exposure agents containing 4-VBC are used in protective coatings and materials. These coatings are applied to surfaces to create a barrier that traps glass fibers, preventing them from becoming airborne. In materials like reinforced plastics and composites, 4-VBC ensures that glass fibers remain embedded within the matrix, enhancing the material’s overall integrity and safety.

Performance and Efficiency of Anti-Exposure Treatments

Treatments using 4-VBC-based anti-exposure agents have shown high performance and efficiency. They effectively reduce the release of glass fibers during manufacturing processes, leading to safer work environments. Additionally, these treatments do not compromise the mechanical properties of the final products. Instead, they often enhance properties like strength and durability by ensuring better fiber distribution and adhesion.

Case Studies or Examples in the Industry

Several industries have successfully implemented 4-VBC-based anti-exposure agents. For instance, the automotive industry uses these agents in the production of reinforced plastic parts to ensure worker safety and product quality. Similarly, the construction industry applies these agents in building materials to prevent glass fiber exposure during installation and use. These case studies demonstrate the practical benefits and effectiveness of using 4-VBC in real-world applications.

Closing Words

4-Vinylbenzyl Chloride (4-VBC) plays a crucial role in polymer chemistry. It is synthesized through straightforward chemical reactions and can be used to form long polymer chains. 4-VBC is integral in producing a wide range of valuable materials, such as ion exchange resins and conductive polymers. Additionally, it helps reduce glass fiber exposure, thereby improving workplace safety. By enhancing the bonding between glass fibers and resins, 4-VBC contributes to the strength and quality of composite materials. Overall, 4-VBC is essential for the advancement of materials used across various industries.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs