Fire Safety Innovations: Exploring Flame Retardant Pentafluoro(Phenoxy)Cyclotriphosphazene (CAS No. 33027-68-8)

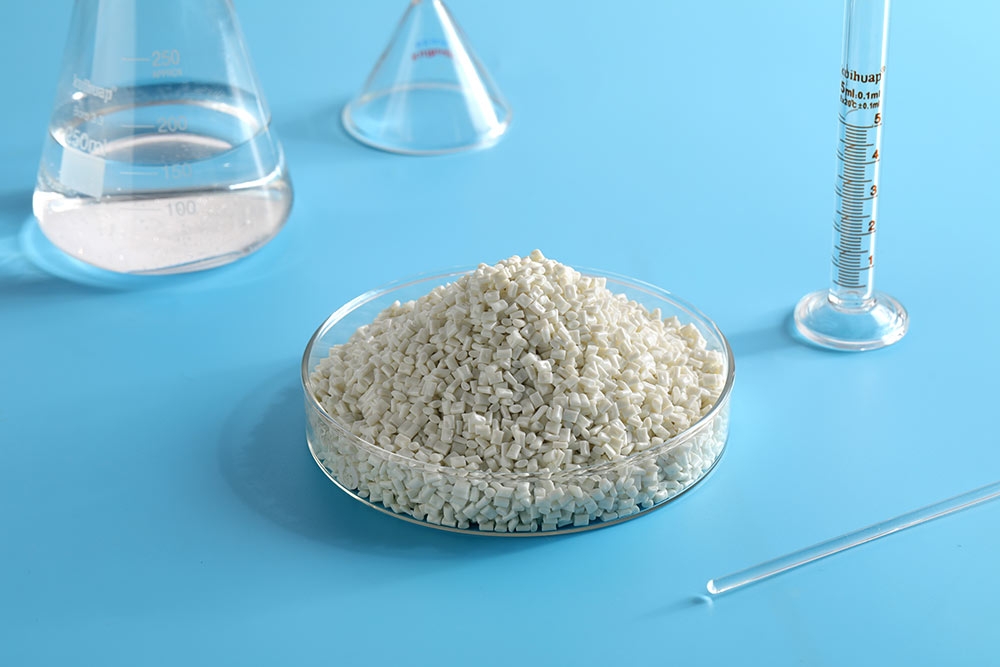

Flame Retardant HFPN(POPFPN), also known as Pentafluoro(Phenoxy)Cyclotriphosphazene (CAS No. 33027-68-8), is a pivotal development from UniVOOK Chemical. Widely applied in electronic materials and textiles, it also serves as a key intermediate in organic synthesis. In electronics, HFPN upholds rigorous fire safety standards, bolstering the resilience and security of electronic devices. Similarly, in textiles, it enhances the flame resistance of fibers, crucial for safety in both consumer and industrial contexts. Flame retardants like HFPN are indispensable, effectively averting fire hazards and safeguarding end-users across diverse industries.

Applications in Electronic Materials

Overview of Electronic Materials Industry

The electronic materials industry is essential for technological progress, supplying critical components for a wide range of applications, from consumer electronics to advanced communication systems. With the constant push towards smaller, more powerful devices, there is an increasing need for materials that can ensure both performance and safety under demanding conditions.

Specific Uses of Flame Retardant HFPN(POPFPN) in Electronic Components

Flame Retardant HFPN(POPFPN) finds extensive use in manufacturing circuit boards, connectors, and enclosures within electronic devices. Its high thermal resistance makes it an optimal choice for components that must endure significant heat stress, ensuring reliable functionality even in environments prone to elevated temperatures.

Benefits of Flame Retardants in Electronic Applications

The primary advantage of integrating Flame Retardant HFPN(POPFPN) into electronic materials is heightened safety. By enhancing the material’s ability to resist ignition and slow down flame propagation, HFPN effectively mitigates the risk of fire hazards in electronic devices. This characteristic is crucial for meeting stringent safety standards and safeguarding both consumers and sensitive electronic equipment globally.

Case Studies or Examples of Successful Applications

A notable application of HFPN is in the production of server enclosures used in data centers. Here, its use has proven instrumental in preventing fire incidents, thus ensuring the protection of valuable equipment and data. Such practical applications underscore HFPN’s reliability and efficacy in safeguarding critical infrastructure from potential fire risks.

Applications in Spinning Industry

Introduction to the Spinning Industry

The spinning industry forms the backbone of textile manufacturing, involving the transformation of fibers such as cotton and wool into yarns or threads. This foundational process supports the production of fabrics used across various sectors, ranging from apparel to industrial textiles.

Role of Flame Retardant HFPN(POPFPN) in Improving Textile Flame Resistance

In textile applications, HFPN is applied during the spinning process to impart flame-retardant properties to fibers. This treatment is particularly vital in textiles used in environments with elevated fire risks, including furnishings for homes, public transport seating, and protective clothing worn by emergency responders.

Comparison with Other Flame Retardants Used in Spinning

Compared to traditional flame retardants that may emit harmful fumes when exposed to heat, HFPN offers a safer alternative with fewer toxic byproducts. Its chemical composition enables seamless integration with fibers, providing effective flame resistance without compromising the natural characteristics of the fabric, such as texture or color.

Impact on Product Durability and Safety

Textiles treated with HFPN not only meet stringent fire safety standards but also exhibit enhanced durability. This improvement in fabric strength and resistance to wear and tear extends the lifespan of textile products, ensuring long-term safety and value across both consumer and industrial applications.

Intermediate in Organic Synthesis

Definition and Importance of Intermediates in Organic Synthesis

Intermediates in organic synthesis are pivotal compounds formed during the middle stages of chemical reactions, essential for progressing towards the final desired product. They facilitate the construction of complex molecular structures from simpler starting materials, influencing the efficiency, cost-effectiveness, and overall success of the synthesis process.

Chemical Properties and Characteristics of Flame Retardant HFPN(POPFPN)

Flame Retardant HFPN(POPFPN), also known as Pentafluoro(Phenoxy)Cyclotriphosphazene, boasts robust thermal stability and a distinctive chemical composition featuring phosphazene rings and pentafluorophenoxy groups. These properties endow it with exceptional resistance to degradation under conditions of heat and oxidation, making it highly suitable for use in high-temperature reactions and as an intermediate in the synthesis of flame retardants.

Examples of Organic Compounds Synthesized Using Flame Retardant HFPN(POPFPN)

Flame Retardant HFPN(POPFPN) serves as a versatile intermediate in the production of various flame-retardant polymers and co-polymers. It is notably incorporated into materials such as polyamides and polyesters, where its integration into molecular structures enhances resistance to ignition and the spread of flames. This application is crucial for developing advanced materials used in safety-critical sectors such as aerospace, automotive, and electronics industries.

Future Trends and Potential Advancements in Organic Synthesis Using This Compound

The future outlook for organic synthesis involving Flame Retardant HFPN(POPFPN) holds promise for advancements in creating sustainable and environmentally friendly flame-retardant materials. Researchers are actively exploring methods to integrate HFPN into biodegradable polymers and are developing novel synthesis pathways aimed at reducing waste and energy consumption. These efforts are geared towards enhancing the eco-friendliness of manufacturing processes while maintaining the efficacy and safety of flame retardant applications.

Environmental and Safety Considerations

Environmental Impact of Flame Retardant HFPN(POPFPN)

Assessing the environmental impact of Flame Retardant HFPN(POPFPN) is crucial due to its widespread use across various industries. While highly effective in fire prevention, concerns exist regarding its potential for bioaccumulation and persistence in ecosystems. Ongoing research endeavors seek to comprehensively understand its long-term effects on the environment and to develop strategies for minimizing any adverse ecological footprint.

Safety Regulations and Guidelines Related to Its Use

The utilization of Flame Retardant HFPN(POPFPN) is strictly governed by stringent safety regulations and guidelines. These regulations mandate rigorous testing and evaluation of the compound for toxicity, persistence, and bioaccumulation before approval for use in consumer products and industrial applications. Adherence to these standards ensures that the benefits of flame retardancy provided by HFPN are balanced with considerations for human health and environmental protection.

Comparison with Other Flame Retardants in Terms of Environmental and Safety Aspects

When compared to alternative flame retardants, HFPN(POPFPN) demonstrates favorable characteristics in terms of effectiveness and safety, particularly under high-temperature conditions. However, like many chemicals used in flame retardation, proper handling and disposal procedures are essential to mitigate potential environmental contamination risks. Ongoing advancements in chemical research aim to enhance the environmental sustainability and safety profiles of flame retardant materials, striving for solutions that offer robust fire protection while minimizing impacts on health and the environment.

CONCLUSION

Flame Retardant HFPN(POPFPN) is a versatile and essential compound widely utilized in electronics, textiles, and organic synthesis. Its outstanding chemical properties ensure enhanced safety and performance, making it crucial for developing flame-retardant materials. However, effective management and adherence to strict regulations are vital due to environmental and safety concerns associated with its use. Future advancements in sustainable practices are poised to expand HFPN(POPFPN)’s applications while promoting environmental responsibility, ensuring its continued role in providing critical flame retardancy across various industries.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs