Exploring Allyl Glycidyl Ether (AGE): Properties, Applications, and Benefits

Allyl Glycidyl Ether (AGE) is a versatile and reactive organic compound containing both an allyl group (-CH2=CH-CH2-) and an epoxy group (-C-O-). Produced by UniVOOK Chemical through the reaction of allyl alcohol and ethylene oxide, AGE(CAS No. 106-92-3) plays a vital role as an intermediate in organic synthesis. Its distinctive molecular structure renders it highly valuable across diverse industries, especially in the synthesis of polymers and various chemicals. AGE’s ability to improve the properties of resins, coatings, adhesives, and other materials underscores its significant contribution to industrial progress.

Chemical Properties of Allyl Glycidyl Ether

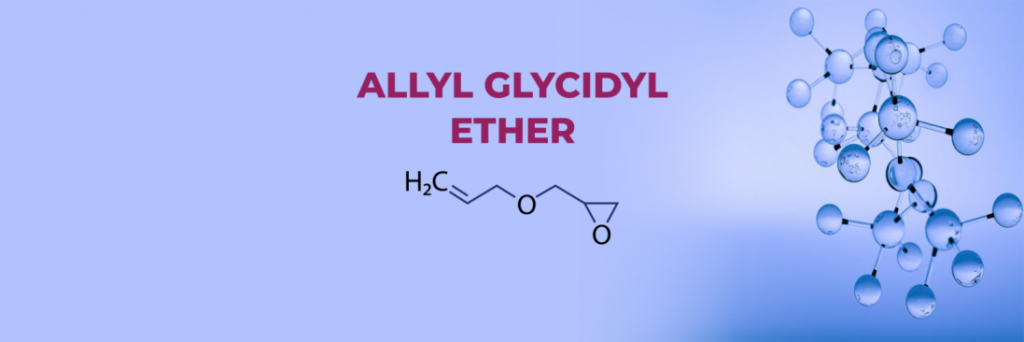

Molecular Structure and Formula

Allyl glycidyl ether (AGE) is a colorless liquid organic compound with the molecular formula C6H10O2. Its structure features both allyl (-CH2=CH-CH2-) and glycidyl (-C-O-) groups, imparting versatility and reactivity crucial for various chemical reactions and industrial applications.

Key Features: Allyl Glycidyl Ether (AGE)

- Polymer Synthesis:

AGE serves as a vital monomer in polymer synthesis, facilitating the production of specialized polymers like allyl resin and epoxy resin. This capability enables the creation of high-performance materials essential across diverse industries.

- Crosslinking Agent:

With its epoxy group, AGE acts effectively as a crosslinking agent, forming a robust three-dimensional network in materials. This enhances their hardness, heat resistance, and chemical durability, crucial for applications requiring strong and resilient materials.

- Synthesis of Functional Materials:

AGE plays a pivotal role in synthesizing functional materials such as photosensitive and colloidal materials. Its unique properties enable the development of advanced materials tailored for specific technological applications.

- Adhesive and Coating Enhancement:

In the adhesive and coating industry, AGE from UniVOOK Chemical enhances adhesion, flexibility, and durability of formulations. This improvement leads to superior performance of adhesives and coatings, ensuring reliability in various industrial applications.

- Functionalizing Polymers:

AGE’s versatility extends to functionalizing polymers by introducing reactive groups, expanding their applications in sectors such as pharmaceuticals, dyes, and surfactants. This capability adds significant value to polymer chemistry advancements.

Industrial Applications

Solvent and Cosolvent Properties

AGE exhibits excellent solvent properties, serving as a cosolvent in coatings, adhesives, and industrial formulations. Its ability to dissolve diverse compounds enhances the formulation and application processes across different industries.

Diluent and Solvent

Used as a diluent and solvent in pigments, inks, dyes, and fragrances, AGE improves consistency and application characteristics of these products. Its compatibility with various substances enhances their performance in industrial settings.

Intermediate in Organic Synthesis

AGE plays a critical role as an intermediate in organic synthesis, particularly in drug synthesis and the production of complex organic compounds. Its reactivity and functional groups are essential for creating advanced materials required in pharmaceutical and chemical industries.

Raw Material for Polyurethane Rubber and Epoxy Resin

As a raw material, AGE enhances the properties of polyurethane rubber and acts as a thinner for epoxy resin formulations. Its contributions improve the effectiveness and durability of these materials in various applications.

Fiber Modifier and Stabilizer

AGE functions as a fiber modifier and stabilizer for chlorinated organic matter, enhancing the stability and performance of synthetic resins and industrial materials. Its role as a reactive diluent further improves material properties in manufacturing processes.

Polymeric Monomer and Intermediate

AGE is pivotal as both a polymeric monomer and intermediate in organic synthesis, leveraging its carbon-carbon double bonds and epoxy bonds to produce a wide array of polymeric materials tailored for specific industrial uses.

Synthesis of Coupling Agents

In industrial chemistry, AGE is used to synthesize coupling agents with unique allyl or epoxy functionalities. These agents enhance the performance and durability of elastomers, epoxy resins, adhesives, and fibers, showcasing AGE’s versatility across various industrial applications.

Environmental and Health Considerations

Toxicological Profile and Safety Measures

Allyl glycidyl ether (AGE) requires careful handling due to its toxicological profile. Exposure to AGE can cause irritation to the skin, eyes, and respiratory tract, and prolonged or repeated exposure may lead to sensitization and organ damage. To mitigate these risks, it is crucial to follow strict safety protocols. This includes using personal protective equipment (PPE) such as gloves, goggles, and respirators, and ensuring adequate ventilation in workplaces where AGE is used or handled.

Environmental Impact and Regulatory Aspects

The production, usage, and disposal of AGE have significant environmental implications. AGE is harmful to aquatic life and can cause long-term adverse effects in aquatic environments. Regulatory agencies have implemented guidelines to manage its environmental impact effectively. Compliance with these regulations, including proper waste treatment and adherence to safety standards, is essential to minimize the ecological footprint of AGE. Companies must align their processes with these regulations to protect the environment and public health.

Advantages and Benefits

Enhancement of Epoxy Resin Properties

AGE enhances the properties of epoxy resins, notably improving their flexibility and impact resistance. This enhancement makes epoxy resins suitable for demanding applications that require durable and resilient materials. Products incorporating AGE can withstand harsh conditions and mechanical stress, expanding the practical applications of epoxy resins in various industries.

Improved Adhesion and Durability in Coatings

In coatings, AGE plays a crucial role in enhancing adhesion and durability. When incorporated into coating formulations, AGE promotes superior adhesion to diverse substrates such as metals, plastics, and glass. This results in coatings that are more durable, providing enhanced protection and aesthetic appeal over extended periods. Improved durability also reduces maintenance needs, contributing to cost savings and sustainability.

Versatility in Formulation and Application

AGE’s versatility extends across different industries, where it can be integrated into various formulations to enhance performance. It improves the properties of adhesives, sealants, and other polymer-based products, offering manufacturers the flexibility to develop customized solutions tailored to specific industrial requirements. This versatility not only boosts product performance but also supports innovation and adaptation to evolving market demands.

Future Trends and Research

Emerging Applications in Advanced Materials

The future of AGE lies in its expanding applications within advanced materials. Researchers are exploring its potential in developing new composites, nanomaterials, and high-performance polymers. These materials are poised to revolutionize sectors such as aerospace, electronics, and renewable energy, driven by AGE’s unique properties. As demand grows for innovative materials, AGE is expected to play a pivotal role in advancing material science and enabling new technological breakthroughs.

Research Advancements and Potential Innovations

Ongoing research is focused on optimizing AGE’s properties and expanding its applications. Scientists are investigating methods to enhance its reactivity, improve environmental sustainability, and develop safer synthesis processes. Innovations include creating AGE-based materials with superior mechanical, thermal, and chemical characteristics, opening new avenues for industrial applications. These advancements promise to deliver significant benefits across various sectors, offering transformative solutions and enhancing the competitiveness of industries utilizing AGE.

Final Thoughts

Allyl Glycidyl Ether (AGE) is an adaptable and reactive organic compound featuring both an allyl group (-CH2=CH-CH2-) and an epoxy group (-C-O-). Produced by UniVOOK Chemical through the reaction of allyl alcohol and ethylene oxide, AGE (CAS No. 106-92-3) serves as a pivotal intermediate in organic synthesis. Its distinct molecular structure renders it highly prized across diverse industries, particularly in the synthesis of polymers and chemicals. AGE plays a crucial role in enhancing the properties of resins, coatings, adhesives, and other materials, underscoring its significant impact on advancing industrial processes and technologies.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs