Ammonium Polyphosphate: A Key Ingredient in Flame-Resistant Products

The Importance of Fire Safety in Modern Industries

In an era where fire safety is paramount, one might wonder: how can industries ensure that their products withstand the ever-present threat of flames? A staggering statistic reveals that fires cause billions in damages annually, leading to devastating losses for businesses and lives alike. This alarming reality prompts manufacturers to seek effective solutions that can mitigate fire risks.

Enter Ammonium Polyphosphate, a versatile and essential flame retardant that plays a critical role in safeguarding materials across various sectors, from construction to textiles and beyond. Ammonium Polyphosphate not only enhances fire resistance but also contributes to overall product safety, making it an invaluable asset in manufacturing. This blog delves into the intricate science behind Ammonium Polyphosphate, exploring its numerous Ammonium Polyphosphatelications and environmental impacts. By highlighting the significance of Ammonium Polyphosphate in modern manufacturing, we can better understand its role in creating safer products and environments, ultimately promoting a culture of fire safety in our daily lives.

The Science Behind Ammonium Polyphosphate

Chemical Composition and Properties

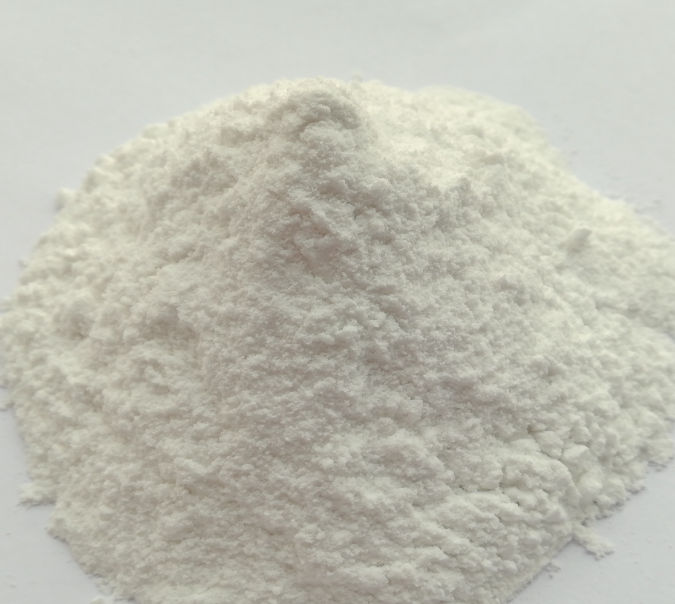

It is a white, crystalline powder, known for its non-hygroscopic and non-flammable characteristics. Its chemical structure, represented as (NH4)n+2PnO3n+1, consists of ammonium and polyphosphate ions. This unique arrangement contributes to its remarkable flame-retardant properties, making it a preferred choice in industries that prioritize safety.

Mechanism of Action

When exposed to high temperatures, Ammonium Polyphosphate undergoes thermal decomposition, releasing non-toxic gases like water vapor and ammonia. These gases dilute combustible vapors in the surrounding atmosphere, effectively cooling the material and suppressing combustion. This dual action not only slows the spread of flames but also provides a protective barrier that enhances the safety of the treated materials.

Intumescent Properties

In addition to its role as a flame retardant, it is a vital component in intumescent coatings. These specialized coatings expand when exposed to heat, forming a char layer that insulates the underlying material from flames. This innovative feature significantly enhances fire resistance, making Ammonium Polyphosphate an indispensable additive in various fire safety Ammonium Polyphosphatelications.

Benefits and Ammonium Polyphosphatelications of Ammonium Polyphosphate

Enhanced Fire Resistance in Construction Materials

Ammonium Polyphosphate is extensively used in the production of fire-resistant construction materials. By incorporating Ammonium Polyphosphate into wood, plywood, and fiberboard, manufacturers can significantly improve the fire safety of these products. This enhancement is critical in creating safer homes, commercial buildings, and furniture, ultimately protecting lives and property.

Versatility Across Industries

Beyond construction, it is a valuable additive in numerous industries, including textiles, electronics, and automotive manufacturing. It is commonly used in fabrics and upholstery to prevent ignition, thereby contributing to fire safety in public spaces, airplanes, and vehicles. Its versatility makes it a go-to solution for manufacturers seeking to enhance the fire resistance of their products.

Polymer Additive for Improved Safety

In the realm of polymer manufacturing, it is used as an additive in various materials, such as polyolefins, polyesters, and thermosetting resins. By imparting flame retardant properties to these polymers, Ammonium Polyphosphate ensures that they meet stringent fire safety standards, making them suitable for Ammonium Polyphosphatelications where fire protection is critical.

Challenges and Solutions in Using Ammonium Polyphosphate

Storage and Shelf Life Considerations

While Ammonium Polyphosphate offers numerous benefits, manufacturers must consider its shelf life and storage requirements. Under optimal conditions, Ammonium Polyphosphate has a shelf life of 24 months. Proper storage is essential to maintain its effectiveness, ensuring that the flame retardant properties are preserved for future use.

Health and Safety Protocols

As with any chemical product, adhering to health and safety guidelines is crucial when using Ammonium Polyphosphate. Manufacturers should consult the Material Safety Data Sheet (MSDS) for detailed safety recommendations. By following established protocols, businesses can ensure safe handling and usage, minimizing any potential risks associated with the product.

Overcoming Environmental Concerns

Despite its many advantages, some concerns about the environmental impact of flame retardants persist. Fortunately, Ammonium Polyphosphate is considered a safer alternative to traditional halogenated flame retardants, as it does not release toxic byproducts during combustion. Ongoing research and development aim to further enhance the sustainability of Ammonium Polyphosphate, making it an even more environmentally friendly choice for manufacturers.

The Environmental Impact of Ammonium Polyphosphate: Safe and Sustainable?

Eco-Friendly Properties

Ammonium Polyphosphate is often lauded for its eco-friendly characteristics. Unlike many conventional flame retardants, Ammonium Polyphosphate does not contain halogens, which are known to produce harmful byproducts. This non-toxic nature makes Ammonium Polyphosphate a favorable option for companies striving to implement sustainable practices in their production processes.

Regulatory Compliance

As environmental regulations become more stringent, industries are increasingly required to adopt safer materials. Ammonium Polyphosphate meets many of these compliance standards, making it a reliable choice for manufacturers looking to align their products with current regulations. By incorporating Ammonium Polyphosphate into their offerings, companies can enhance their reputation as environmentally responsible businesses.

Future Developments and Innovations

The landscape of fire retardants is evolving, and research into alternative, more sustainable options continues to grow. UniVOOK Chemical, a leading producer of it, is at the forefront of this innovation. By investing in research and development, UniVOOK aims to improve the efficacy and environmental footprint of Ammonium Polyphosphate, ensuring that it remains a top choice for industries seeking safe and effective fire protection solutions.

Conclusion

It is undeniably a cornerstone of modern fire safety across various industries. Its scientific foundation reveals a sophisticated chemical structure that enables it to function effectively as a flame retardant, significantly enhancing the safety of construction materials, textiles, and polymers. By forming protective barriers and releasing non-toxic gases during combustion, Ammonium Polyphosphate effectively slows the spread of flames, safeguarding lives and properties.

While challenges such as storage, health protocols, and environmental concerns exist, ongoing advancements in research and safety regulations continually address these issues, paving the way for a safer future. The push for improved fire safety measures and environmental sustainability makes Ammonium Polyphosphate even more relevant today. As manufacturers and industries prioritize both safety and eco-friendliness, Ammonium Polyphosphate will undoubtedly play a crucial role in shaping the landscape of fire retardants for years to come, helping to create safer environments in homes, workplaces, and public spaces alike.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs