Ammonium Polyphosphate: A Vital Flame Retardant

Captivating Insights into Ammonium Polyphosphate

Did you know that more than 75% of all fires are preventable? One key player in fire prevention is Ammonium Polyphosphate (APP), a compound that acts as an essential flame retardant in various industries. As safety regulations tighten and fire hazards remain a significant concern, understanding the properties and applications of APP is more crucial than ever. This blog explores the market status, characteristics, and innovative applications of ammonium polyphosphate, focusing on its growing importance in today’s world.

Market Overview and Growth Potential

Recent Market Size and Forecast

As of 2023, the global market for Ammonium Polyphosphate is estimated to be valued at approximately USD 1.5 billion. With the increasing emphasis on fire safety across various sectors, the compound is expected to witness substantial growth in the coming years. Industry analysts project a compound annual growth rate (CAGR) of around 6.5% from 2023 to 2028, which could elevate the market size to approximately USD 2.1 billion by 2028. This growth is driven by rising demands in construction, automotive, and textiles, where fire safety is paramount.

Factors Driving Market Growth

Several factors contribute to the increasing demand for ammonium polyphosphate. The first is the growing awareness of fire safety regulations in residential and commercial buildings. Governments and organizations are enforcing stricter standards, pushing manufacturers to seek effective flame retardants. Additionally, the rise in manufacturing processes that incorporate APP—especially in polymers and coatings—further stimulates market growth. Finally, innovation in product formulations enhances APP’s effectiveness, making it an attractive choice for various applications.

Regional Market Trends

The demand for ammonium polyphosphate varies by region, with North America and Europe currently leading the market due to stringent fire safety regulations. However, the Asia-Pacific region is emerging as a significant player, fueled by rapid industrialization and increasing infrastructure projects. Countries like China and India are investing heavily in fire safety measures, creating a promising landscape for APP.

Chemical Properties and Structure

Unique Chemical Composition

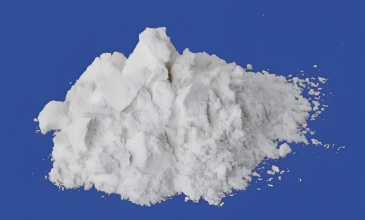

Ammonium polyphosphate (APP) is represented by the chemical formula (NH4PO3)n, where “n” indicates the degree of polymerization. This compound is a white, non-hygroscopic, crystalline powder with a molecular weight of approximately 149.086 g/mol. Its unique structure allows it to perform effectively as a flame retardant.

Flame Retardant Mechanism

When exposed to high temperatures, ammonium polyphosphate undergoes thermal decomposition. It releases non-toxic gases like water vapor and ammonia, which dilute flammable gases and cool the surrounding material. This process not only suppresses combustion but also creates a protective char layer that acts as a barrier to slow the spread of flames, enhancing the overall safety of the material.

Stability and Shelf Life

Under proper storage conditions, ammonium polyphosphate boasts a shelf life of 24 months. Its stability makes it suitable for long-term use in various applications, ensuring that manufacturers can rely on its performance over time.

Applications of Ammonium Polyphosphate

Fire Safety in Construction

One of the primary applications of ammonium polyphosphate is in the construction industry. APP is incorporated into materials such as wood, plywood, and fiberboard to enhance their fire resistance. By using APP-treated materials, builders can create safer structures that comply with modern fire safety standards, ultimately protecting lives and property.

Versatility in Polymer Manufacturing

Ammonium polyphosphate is widely used as an additive in various polymers, including polyolefins and polyesters. Its incorporation imparts flame retardant properties to these materials, making them suitable for applications where fire safety is crucial. Industries such as automotive and electronics benefit significantly from the enhanced safety profiles provided by APP.

Innovation in Intumescent Coatings

Intumescent coatings, which expand when exposed to heat, are another critical application for ammonium polyphosphate. These coatings form a protective char layer that insulates underlying materials, significantly delaying the spread of flames. This technology is particularly valuable in protecting structural elements in buildings, ships, and industrial facilities.

Health and Safety Considerations

Material Safety Data Sheet (MSDS) Guidance

To ensure safe handling and application of ammonium polyphosphate, users are encouraged to consult the Material Safety Data Sheet (MSDS). The MSDS provides crucial information regarding health and safety guidelines, including appropriate protective measures during handling and storage.

Environmental Impact

Ammonium polyphosphate is regarded as a relatively non-toxic compound when used as directed. Its decomposition products, such as water vapor and ammonia, are generally considered safe, making it an environmentally friendly choice among flame retardants. The use of APP can help meet sustainability goals in various industries.

Handling and Storage Recommendations

For optimal safety, ammonium polyphosphate should be stored in a cool, dry place, away from direct sunlight and incompatible substances. Proper training in handling procedures is essential to mitigate risks associated with dust inhalation or skin contact.

Custom Manufacturing Solutions by UniVOOK Chemical

Tailored Approaches to Chemical Manufacturing

UniVOOK Chemical stands out as a leading supplier of ammonium polyphosphate, offering custom manufacturing solutions that cater to the specific needs of clients. The company collaborates closely with customers to create tailored formulations that meet unique performance criteria, ensuring that every product is optimized for its intended application.

Comprehensive Support from Concept to Production

The custom manufacturing process at UniVOOK Chemical encompasses a wide range of services, from initial idea assessment to final production. This integrated approach allows clients to benefit from expertise in chemical synthesis, quality control, and efficient supply chain management. By partnering with UniVOOK, businesses can streamline their operations and reduce time to market.

Commitment to Quality and Flexibility

Quality assurance is a top priority for UniVOOK Chemical. The company implements strict quality management protocols throughout the manufacturing process, ensuring consistent product performance. Additionally, their flexible manufacturing capabilities allow them to adapt to changing market demands, supporting clients as they scale up production or innovate new products.

Conclusion

Ammonium polyphosphate is an essential flame retardant with diverse applications across various industries. Its unique chemical properties and effective flame suppression capabilities make it a critical component in enhancing fire safety. As the market for APP continues to grow, driven by increasing regulations and safety standards, suppliers like UniVOOK Chemical are well-positioned to meet the evolving needs of manufacturers worldwide. By leveraging their expertise in custom manufacturing, they provide tailored solutions that ensure safety without compromising on performance. Understanding and utilizing ammonium polyphosphate is not just a business decision; it’s a commitment to safer, more sustainable practices in an increasingly fire-conscious world.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs