The Role of 2,3-Difluoro-4-Vinylphenol as a Polymeric Chain Extender

Polymer chain extension helps improve the properties of polymers by linking their chains together. One key chain extender is 2,3-Difluoro-4-Vinylphenol (DFVP). DFVP is used to make photoresist polymers, crosslinked fibers, coupling agents, and conductive polymers. It is also used in pharmaceuticals. Additionally, DFVP acts as an initiator for the polymerization of various copolymers. UniVOOK Chemical produces DFVP, which serves as a bifunctional styrene monomer in organic synthesis. Besides DFVP, UniVOOK manufactures and distributes other industrial and electronic-grade styrene derivatives. The company has a total production capacity of 6,000 metric tons. Chain extenders like DFVP are essential for creating high-quality polymers used in many industries.

Structure and Properties of 2,3-Difluoro-4-Vinylphenol

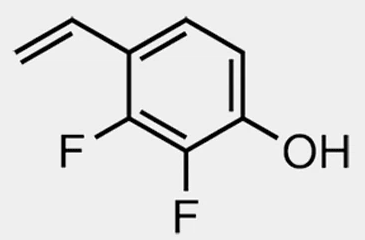

Chemical Structure of DFVP

2,3-Difluoro-4-vinylphenol, commonly known as DFVP, has a distinct chemical structure. The molecule consists of a benzene ring, which is a six-carbon ring with alternating double bonds. Attached to this ring are three important groups. First, there are two fluorine atoms attached to the second and third carbon atoms of the ring. These fluorine atoms are known for their ability to influence the chemical behavior of the molecule. Second, there is a vinyl group attached to the fourth carbon atom. The vinyl group is a two-carbon unit with a double bond, which makes DFVP reactive and useful in polymer chemistry. The presence of the hydroxyl group (-OH) on the ring also plays a significant role in the molecule’s properties. This simple yet effective structure allows DFVP to interact with various polymers, enhancing their characteristics.

Physical and Chemical Properties Relevant to Polymer Chemistry

DFVP exhibits several physical and chemical properties that make it valuable in polymer chemistry. Physically, DFVP is a solid at room temperature, which makes it easy to handle and incorporate into polymer systems. It has a relatively low melting point, allowing it to mix well with other components during polymerization. Chemically, DFVP is reactive due to the presence of the vinyl group and the hydroxyl group. The vinyl group can undergo polymerization, forming strong bonds with polymer chains. The hydroxyl group can form hydrogen bonds, which can enhance the stability and strength of the polymer. Additionally, the fluorine atoms in DFVP contribute to its chemical stability, making the resulting polymers resistant to degradation. These properties ensure that DFVP can effectively modify polymers, improving their performance in various applications.

Mechanism of Action as a Chain Extender

Explanation of How DFVP Interacts with Polymer Chains

DFVP acts as a chain extender by interacting with the ends of polymer chains. When added to a polymer mixture, the vinyl groups of DFVP react with the active ends of the polymer chains. This reaction links two polymer chains together, effectively extending the length of the chains. The hydroxyl groups in DFVP also play a role by forming hydrogen bonds with other polymer chains. This creates a network of interconnected chains, which enhances the overall structure of the polymer. The fluorine atoms in DFVP help stabilize these interactions, ensuring that the chains remain connected. By linking polymer chains in this way, DFVP increases the molecular weight of the polymer, leading to improved mechanical properties.

Impact on Molecular Weight and Polymer Properties

The interaction of DFVP with polymer chains results in an increase in molecular weight. Higher molecular weight polymers typically exhibit better mechanical strength and durability. DFVP achieves this by effectively connecting shorter polymer chains into longer, more robust chains. This extension of the polymer chains reduces the number of chain ends, which can lead to a more uniform and stable polymer network. As a result, the modified polymer shows enhanced properties such as increased tensile strength and elasticity. Additionally, the presence of DFVP can improve the thermal stability of the polymer, allowing it to withstand higher temperatures without degrading. These improvements make DFVP a valuable additive in the production of high-performance polymers.

Applications of 2,3-Difluoro-4-Vinylphenol in Polymer Systems

Use in Specific Polymer Matrices

DFVP is used in various polymer matrices, including styrene-based polymers and polyurethane. In styrene-based polymers, DFVP enhances the polymer’s strength and durability. It helps in creating a more interconnected polymer network, which improves the material’s resistance to cracking and breaking. In polyurethane systems, DFVP contributes to the flexibility and resilience of the polymer. It allows the polyurethane to maintain its shape and performance under stress. The versatility of DFVP makes it suitable for a wide range of polymer systems, allowing manufacturers to tailor the properties of their products to meet specific requirements.

Examples of Polymers Modified by DFVP

Several polymers have been successfully modified using DFVP. One example is polystyrene, where DFVP is added to improve its impact resistance and thermal stability. Another example is polyurethane, where DFVP enhances the material’s flexibility and strength. Additionally, DFVP has been used in epoxy resins to increase their toughness and adhesive properties. These modifications demonstrate the effectiveness of DFVP in enhancing the performance of various polymers. By incorporating DFVP, manufacturers can produce polymers that meet higher standards of quality and durability, suitable for demanding applications.

Benefits in Terms of Mechanical and Thermal Properties

The incorporation of DFVP into polymers brings several benefits, particularly in mechanical and thermal properties. Mechanically, polymers modified with DFVP exhibit increased tensile strength and elasticity. This means that the materials can withstand greater forces without breaking and can return to their original shape after being stretched. Thermally, DFVP-enhanced polymers have improved resistance to heat. They can maintain their integrity and performance at higher temperatures, making them suitable for applications that involve exposure to heat. Additionally, DFVP contributes to the overall durability of the polymers, reducing the likelihood of degradation over time. These benefits make DFVP a valuable additive for producing high-quality, reliable polymer materials.

Future Directions and Research

While DFVP has proven to be a valuable additive in polymer chemistry, ongoing research continues to explore its full potential. Future studies aim to optimize the concentration of DFVP in various polymer systems to achieve the best possible properties. Researchers are also investigating the environmental impact of DFVP-modified polymers to ensure they meet sustainability standards. Additionally, new applications for DFVP are being explored in advanced materials, such as nanocomposites and biodegradable polymers. These efforts will help to expand the use of DFVP and improve the performance of a wide range of polymer-based products.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs