How Antioxidant DLTDP Improves Durability and Life of Materials

Antioxidants are important in material science. They help protect materials from damage caused by stress, heat, and oxidation. One such antioxidant is DLTDP (Di-tert-butyl-4,6-dimethylphenylphosphonite). It is gaining attention in many industries. DLTDP is known for its strong performance in protecting materials from degradation due to heat and oxygen. This makes it ideal for applications where materials are exposed to these conditions. UniVOOK Chemical offers DLTDP as a reliable solution to improve the durability and lifespan of materials. Our antioxidant helps materials resist the harmful effects of oxidation. Trust UniVOOK Chemical for better protection and stability in industrial uses.

What is DLTDP?

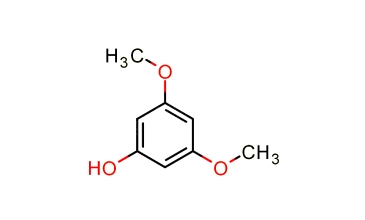

Definition and Chemical Composition of DLTDP

DLTDP stands for Di-tert-butyl-4,6-dimethylphenylphosphonite. It is a type of antioxidant used in material science. Its chemical formula is C14H21O2P. The structure includes a phosphorus atom bonded to two tert-butyl groups and a 4,6-dimethylphenyl group. This specific structure makes DLTDP effective in stabilizing materials against oxidation and degradation.

History and Development of DLTDP as an Antioxidant

DLTDP was first developed as part of the search for more effective antioxidants in various industries. Over time, researchers found that it provided excellent protection against the damaging effects of heat and oxygen on materials. This led to its increased use in different industrial sectors. It gained popularity due to its high efficiency and low toxicity compared to other antioxidants. Today, it is widely used in several fields, particularly in plastics, rubber, and synthetic materials.

General Use in the Stabilization of Plastics, Rubber, and Other Synthetic Materials

DLTDP is commonly used in the stabilization of materials like plastics, rubber, and other synthetic compounds. It helps to prevent degradation caused by exposure to heat, light, and oxygen. In plastics, it prevents yellowing and brittleness, which can occur when the material is exposed to UV radiation. In rubber, it enhances resistance to cracking and aging, especially when used in automotive or industrial applications. DLTDP ensures that these materials last longer, even under harsh conditions.

Mechanism of Action

How DLTDP Works on a Molecular Level to Prevent Oxidation

DLTDP works by interacting with free radicals that cause oxidation. Oxidation happens when materials react with oxygen, breaking down the material over time. DLTDP helps to stop this process by donating electrons to these free radicals. By doing so, DLTDP neutralizes the radicals, preventing them from causing further damage to the material. This helps keep the materials stable and intact for longer periods.

Role in Scavenging Free Radicals and Inhibiting Oxidative Reactions in Materials

The key function of DLTDP is to act as a free radical scavenger. Free radicals are highly reactive molecules that cause oxidation and deterioration in materials. DLTDP captures these radicals before they can interact with the material. By preventing this reaction, DLTDP stops oxidative degradation. This is particularly important in protecting materials used in environments with high temperatures or exposure to oxygen, where oxidation is more likely to occur.

How DLTDP Stands Out in Comparison to Other Common Antioxidants

DLTDP is considered more efficient than other common antioxidants for certain applications. Compared to traditional antioxidants like hindered phenols or phosphites, DLTDP offers better protection under high-temperature conditions. It also performs well in preventing oxidation in materials exposed to UV light. While other antioxidants may break down more quickly in extreme conditions, DLTDP remains stable and effective for longer periods, making it a preferred choice in many industrial applications.

Benefits of Using DLTDP in Materials

Improved Durability

One of the main benefits of using DLTDP is the improved durability it provides. Materials treated with DLTDP are more resistant to environmental stressors such as heat, UV radiation, and chemical exposure. These stressors can cause materials to weaken, crack, or degrade over time. However, DLTDP helps to protect against these effects, making materials last longer and perform better under challenging conditions. This is especially important in industries where long-lasting materials are essential, like in automotive or construction.

Extended Lifespan

Another key benefit of DLTDP is that it extends the lifespan of materials. By preventing oxidation and degradation, DLTDP helps materials maintain their structural integrity and functionality over time. This means that products can stay in use longer without needing replacements or repairs. For industries, this leads to lower maintenance costs and better product performance. Whether in automotive parts, packaging, or construction materials, using DLTDP can significantly reduce the frequency of replacements and the costs associated with them.

Economic and Environmental Impact

Using DLTDP not only improves material performance but also offers economic and environmental benefits. By enhancing the durability of materials, DLTDP reduces the need for frequent replacements. This leads to cost savings for manufacturers and end-users alike. Additionally, by extending the lifespan of materials, DLTDP helps reduce material waste, which is beneficial for the environment. Industries such as automotive, construction, and packaging can all benefit from these advantages, as they rely on long-lasting materials to reduce both costs and waste.

Applications of DLTDP in Various Industries

Automotive

In the automotive industry, DLTDP is used to improve the durability of rubber seals, gaskets, and tires. These parts are often exposed to high temperatures, UV radiation, and mechanical stress, which can cause them to deteriorate quickly. DLTDP helps protect these parts by preventing oxidation, ensuring they last longer and maintain their performance. This reduces the need for replacements and enhances the overall quality and reliability of automotive products.

Plastics

In the plastics industry, DLTDP is used to stabilize molded parts that are exposed to high temperatures or UV radiation. Without protection, plastics can degrade, discolor, or become brittle. DLTDP prevents this by neutralizing free radicals and inhibiting oxidation. This allows the plastics to retain their strength and appearance over time, making them ideal for use in outdoor applications, electronics, and automotive parts.

Electronics

DLTDP is also used in the electronics industry to prevent degradation in insulation materials and wires. In electronics, components are often exposed to heat and oxygen, which can lead to the breakdown of insulation and wire coatings. DLTDP helps protect these materials by preventing oxidative damage, which can lead to short circuits or system failures. Its use ensures that electronics remain safe and functional for longer periods.

Packaging

In the packaging industry, DLTDP is used to extend the shelf life of plastic packaging. Packaging materials are often exposed to UV light, oxygen, and heat, which can cause them to degrade, discolor, and lose their strength. DLTDP helps prevent these effects, allowing the packaging to maintain its integrity and appearance for longer periods. This is especially important in the food and beverage industry, where packaging needs to protect products from environmental factors while maintaining its visual appeal.

Protect Your Materials with DLTDP Today

DLTDP is a powerful antioxidant that protects materials from heat, oxygen, and degradation. It helps keep plastics, rubber, and other materials strong and durable. Whether in automotive, packaging, or electronics, DLTDP extends the life of your products. Don’t let oxidation damage your materials. Choose DLTDP for better performance and longer-lasting results. Contact us now to learn how DLTDP can improve your materials and save you costs. Trust DLTDP for reliability and protection.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs