Role and Applications of Butoxyethyl Methacrylate in Modern Industries

Butoxyethyl Methacrylate (BEMA) is a chemical compound with a unique structure, featuring a methacrylate group bonded to a butoxyethyl group. This configuration imparts several important properties to BEMA. Its versatility has made it increasingly valuable across various industries, particularly in the production of materials and coatings. BEMA’s role as a key monomer is driving improvements in performance and quality, positioning it as an essential component in the development of innovative materials and coatings. Could its expanding importance lead to further breakthroughs across multiple fields?

What is Butoxyethyl Methacrylate?

Definition and Chemical Composition of Butoxyethyl Methacrylate

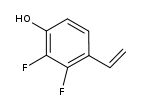

Butoxyethyl Methacrylate (BEMA) is a chemical compound composed of a methacrylate group attached to a butoxyethyl group. This distinctive structure sets it apart from other monomers. The methacrylate portion is reactive, while the butoxyethyl group contributes to its solubility. The combination of these functional groups gives BEMA its unique properties, making it valuable in various industrial applications.

Synthesis and the Chemical Reactions Involved

BEMA is synthesized through a chemical reaction known as esterification, where butoxyethanol reacts with methacrylic acid. This process typically occurs in the presence of an acid catalyst. While the esterification is a straightforward reaction, careful control of conditions is necessary to achieve the desired properties and ensure the purity of the product, which is crucial for its industrial applications.

Properties That Make It Valuable for Industrial Use

BEMA offers several beneficial properties. It is highly soluble in a variety of solvents, making it easy to mix with other chemicals in industrial processes. Its flexibility makes it particularly suitable for coatings and adhesives, where durability and resilience are essential. Additionally, BEMA-based materials exhibit excellent durability, providing long-lasting performance in industries requiring robust materials. These characteristics make BEMA an indispensable component for a wide range of industrial uses.

Key Applications in Modern Industries

Coatings and Paints

BEMA is commonly used in the formulation of coatings and paints, particularly in automotive, architectural, and industrial applications. The inclusion of BEMA enhances the flexibility of these coatings, reducing the likelihood of cracking or peeling. It also improves their durability and resistance to wear. BEMA-based coatings are more resilient to environmental conditions, making them ideal for use in demanding weather environments.

Adhesives and Sealants

In the adhesive and sealant industry, BEMA enhances bonding performance. It improves adhesion to a variety of surfaces, including plastics, metals, and glass. The incorporation of BEMA also boosts flexibility, allowing adhesives and sealants to maintain their integrity under stress. This results in stronger, more reliable materials for a wide range of industrial applications.

Polymerization and Plastic Production

BEMA is utilized in polymerization, particularly in copolymerization processes to enhance the properties of plastics. It helps create plastics that are more flexible, durable, and resistant to chemicals. BEMA is essential in the production of acrylics, resins, and various other polymer-based materials, which are crucial in industries such as construction, automotive, and packaging.

Textile and Leather Finishing

In the textile and leather industries, BEMA improves the durability and flexibility of materials. When incorporated into finishes, it strengthens the fabric and enhances flexibility, making it particularly valuable for products such as clothing and upholstery. Its ability to improve the strength and pliability of textiles and leather makes it a key ingredient in finishing treatments.

Why Choose UniVOOK Chemical‘s Butoxyethyl Methacrylate

UniVOOK Chemical‘s Butoxyethyl Methacrylate Product

UniVOOK Chemical offers a high-quality version of Butoxyethyl Methacrylate. This product is used as an intermediate in the synthesis of photoresist polymers, crosslinked fibers, coupling agents, and conductive polymers. It is also a crucial raw material in semiconductor production. As a bifunctional styrene monomer, it plays a versatile role in various chemical processes, making it an essential component across different industries.

High-Quality Butoxyethyl Methacrylate

UniVOOK Chemical’s Butoxyethyl Methacrylate boasts a minimum purity of 99%. This high purity ensures that the product meets the stringent demands of industries requiring reliable and consistent materials. The product’s quality and dependability make it a top choice for numerous industrial applications.

Product Specifications

UniVOOK Chemical’s Butoxyethyl Methacrylate is available in both industrial and electronic grades. With a molecular weight of 186.25 g/mole, this product is ideal for use in a wide range of applications, from industrial manufacturing to advanced electronic processes, offering versatility and reliability for various industries.

Act Now

Butoxyethyl Methacrylate (BEMA) is a crucial component across many industries, including coatings, adhesives, plastics, and more. UniVOOK Chemical provides high-quality BEMA with a purity of 99%, meeting the diverse needs of your applications. With both industrial and electronic grade options available and a molecular weight of 186.25 g/mole, our product is perfect for your manufacturing requirements.

Order today and experience the superior quality of UniVOOK BEMA! Whether you’re in coatings, adhesives, or polymer production, our BEMA will enhance your products. Don’t miss the opportunity to work with the best materials available. Contact us now to learn more or place your order!

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs