What Makes EVA Wax Better In Vaious Uses?

Have you ever wondered what allows industries to create high-performance plastics, advanced adhesives, and durable coatings? The answer lies in innovative materials like EVA Wax. This polar wax, known for its exceptional compatibility and performance-enhancing properties, has revolutionized industries ranging from plastics to inks. Let’s explore the industrial magic of EVA Wax and how UniVOOK Chemical leads the way as a reliable supplier.

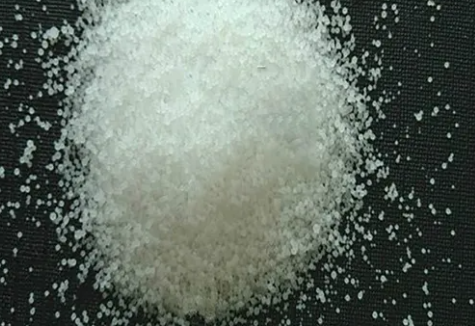

What is EVA Wax?

Understanding the Chemistry Behind EVA Wax

EVA Wax, short for ethylene-vinyl acetate wax, is a low molecular weight copolymer formed by polymerizing ethylene (a non-polar monomer) with vinyl acetate (a strongly polar monomer). This unique combination creates a material with excellent compatibility with both polar and non-polar substances. Its low crystallinity ensures superior toughness and impact resistance, making it a versatile choice in various industrial applications.

Key Characteristics of EVA Wax

EVA Wax offers a host of beneficial properties:

Low Viscosity: Ensures smooth processing.

High Softening Point: Improves temperature resilience.

Good Hardness and Thermal Stability: Ideal for demanding environments.

Low Volatility: Reduces emissions during high-temperature processes.

These qualities make EVA Wax an indispensable material for industries seeking improved performance and durability in their products.

Applications of EVA Wax in Industry

Enhancing Pigment and Filler Masterbatches

EVA Wax serves as a dispersant, lubricant, and compatibilizer in pigment, filler, and additive masterbatches. Its excellent dispersion capabilities ensure even distribution of pigments and fillers, enhancing the aesthetic and structural integrity of finished products.

Supporting Rubber and Plastic Processing

In rubber and plastic manufacturing, EVA Wax acts as a processing lubricant and release agent. It reduces friction during molding, minimizes wear and tear on equipment, and facilitates easy demolding of finished products. As a compatibilizer, it bridges the gap between materials with differing polarities, improving blend homogeneity.

Revolutionizing Ink and Coating Technologies

EVA Wax is widely used as an ink dispersant and anti-scratch agent. Its smooth dispersion ensures vibrant and consistent prints, while its hardness adds a protective layer to prevent scratches and abrasions in printed materials and coatings.

Optimizing Hot Melt Adhesives

In adhesive manufacturing, EVA Wax functions as a viscosity regulator. It stabilizes adhesive formulations and improves bonding strength, ensuring the adhesive performs reliably across varying temperatures and substrates.

Why Choose UniVOOK Chemical for EVA Wax?

A Global Leader in Specialty Chemicals

UniVOOK Chemical is a trusted name in the specialty chemicals industry. With over 15 years of experience, the company has positioned itself as a leading producer, custom manufacturer, and global distributor of industrial and biochemical materials. Headquartered in Shanghai, China, with offices in Europe and Singapore, UniVOOK Chemical operates three production sites and partners with an extensive network to serve clients worldwide.

Commitment to Quality and Innovation

UniVOOK Chemical emphasizes:

Advanced R&D Facilities: Investments in cutting-edge research labs ensure continuous innovation.

Custom Manufacturing: Tailored solutions for unique customer needs.

Global Distribution Network: Efficient supply chains for timely delivery.

These factors make UniVOOK Chemical a preferred supplier for businesses looking to stay competitive in their industries.

Meeting Industrial Needs with EVA Wax Solutions

Pharmaceuticals and Pesticides

EVA Wax finds applications in pharmaceutical and pesticide formulations where its low volatility and compatibility enhance the stability and performance of active ingredients.

New Materials and Electronics

The demand for lightweight, durable materials in electronics and new materials sectors is growing. EVA Wax contributes by providing improved toughness, impact resistance, and processing efficiency.

Coatings and Resins

In the coatings and resins industry, EVA Wax improves the hardness and scratch resistance of products. It is particularly valuable in the production of high-performance industrial and automotive coatings.

Cosmetics and Food Additives

UniVOOK Chemical’s EVA Wax is formulated to meet the stringent requirements of the cosmetics and food industries. Its thermal stability and non-toxic properties make it suitable for sensitive applications.

Why EVA Wax Matters in Today’s Industries

Driving Efficiency and Sustainability

In today’s fast-paced industrial environment, companies are under increasing pressure to improve efficiency and adopt more sustainable practices. EVA Wax aligns perfectly with these goals, providing multiple benefits that help businesses stay competitive while reducing their environmental footprint. First, it reduces waste during processing by improving the flow of materials and enhancing compatibility, thus optimizing manufacturing processes and minimizing scrap. Second, EVA Wax contributes to the longevity of end products by enhancing their mechanical properties, such as toughness and impact resistance, which helps reduce the need for replacements and repairs. Lastly, its low volatility and minimal emissions during processing help minimize the environmental impact, making it an eco-friendly choice for industries looking to meet sustainability goals and regulatory requirements.

Versatile Applications Across Sectors

The versatility of EVA Wax makes it indispensable in various industries. Its wide range of applications spans from improving the mechanical properties of plastics, such as enhancing flexibility and strength, to optimizing advanced adhesives for diverse bonding requirements. Additionally, EVA Wax plays a critical role in coatings, inks, rubber, and even cosmetics, demonstrating its adaptability across sectors. Whether in automotive manufacturing, electronics, or packaging, EVA Wax enhances product performance and quality, proving itself as an essential material for modern manufacturing needs. With its ability to meet the diverse demands of different industries, EVA Wax truly is a game-changer in the world of industrial materials.

The UniVOOK Chemical Advantage

Tailored Solutions for Every Industry

UniVOOK Chemical’s focus on customized solutions ensures that their EVA Wax meets the unique demands of every client. Whether it’s a specialized grade for electronics or a high-durability variant for automotive coatings, UniVOOK Chemical delivers.

Expertise and Reliability

With a team of highly qualified experts and a strong commitment to technological innovation, UniVOOK Chemical has built a reputation for reliability. Their ability to identify emerging market needs and deliver high-quality solutions sets them apart.

Partnering for Success

UniVOOK Chemical collaborates closely with clients to provide not just products, but strategic advantages. Their efficient supply chain, technical support, and global presence ensure seamless operations for businesses worldwide.

Final Thoughts

EVA Wax is a cornerstone of industrial innovation, enabling advancements across multiple sectors. With its unique properties and versatile applications, it is a material that drives efficiency, performance, and sustainability.

UniVOOK Chemical stands as a trusted partner in this journey, offering high-quality EVA Wax and exceptional service. As industries evolve, UniVOOK Chemical’s expertise, innovation, and commitment to excellence will continue to empower businesses globally.

For more information and tailored solutions, explore UniVOOK Chemical’s offerings and discover how they can elevate your industrial operations.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs