Versatile Flame Retardant: Diphenyl(4-Vinylbenzyl)Phosphine Oxide

(CAS No. 741-41-3)

Flame retardants play a critical role in bolstering the safety of electronic materials by impeding or slowing down the combustion process. Among these, Diphenyl(4-Vinylbenzyl)Phosphine Oxide (CAS No. 741-41-3), known as EPO, stands as a standout. EPO not only effectively suppresses flames in various electronic components but also serves as a valuable intermediary in organic synthesis. Its distinct chemical structure grants EPO stability and compatibility with diverse polymers used in electronics. UniVOOK Chemical specializes in supplying EPO, customizing production to meet specific industrial requirements. This flexibility ensures seamless integration of EPO into intricate manufacturing processes, thereby enhancing both the safety and functionality of electronic materials.

Properties of Diphenyl(4-Vinylbenzyl)Phosphine Oxide (EPO)

– Chemical Structure and Molecular Formula

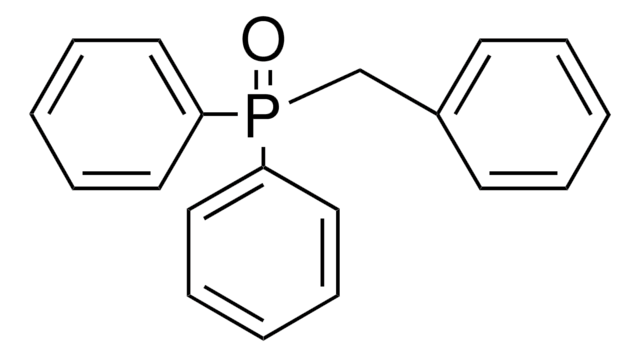

Diphenyl(4-vinylbenzyl)phosphine oxide (EPO) possesses the chemical formula C20H17OP and is classified as a phosphine oxide. Its structure includes a phosphorus atom double-bonded to an oxygen atom, with additional bonds to a benzyl group and two phenyl groups. This arrangement enhances EPO’s chemical robustness and reactivity, crucial for its functional properties.

– Physical Properties

EPO appears as a white to off-white crystalline powder with a melting point typically between 90°C to 95°C. This characteristic demonstrates its stability under moderate heat conditions. Solubility-wise, EPO exhibits moderate solubility in common organic solvents such as methanol and chloroform, facilitating its application in various synthetic processes where such solvents are prevalent.

– Thermal Stability and Decomposition Temperature

One of EPO’s notable attributes is its excellent thermal stability, with a decomposition temperature exceeding 300°C. This high thermal resilience ensures that EPO maintains structural integrity and functionality even under demanding conditions of high-temperature processing, making it suitable for applications requiring robust flame retardant properties.

Flame Retardant Properties

– Mechanism of Action as a Flame Retardant

EPO functions primarily through a radical trapping mechanism during combustion. The phosphorus component within its molecular structure acts to capture and neutralize free radicals generated in the presence of heat or flames. This action effectively inhibits the rapid spread of fire, enhancing fire safety measures in electronic and other materials.

– Effectiveness in Reducing Flammability and Smoke Generation

In practical applications, EPO significantly reduces both the flammability and smoke emission characteristics of treated materials. When exposed to fire, EPO promotes the formation of a protective char layer on the material’s surface. This char barrier acts as an insulating shield, limiting oxygen access and thereby mitigating flame propagation while reducing the release of harmful smoke particles.

– Compatibility with Different Polymers Used in Electronic Materials

Due to its versatile chemical structure, EPO seamlessly integrates with various polymers employed in electronic materials. It blends effectively with epoxy resins, polyamides, and polycarbonates without compromising the physical properties of the base materials. This compatibility ensures that electronic components retain their structural integrity and functionality, crucial for maintaining operational reliability under fire conditions.

Applications in Electronic Materials

– Specific Electronic Materials Where EPO is Commonly Used

EPO finds widespread application in electronic materials, particularly in the formulation of flame-retardant coatings for wires, cables, and enclosures. Its incorporation ensures compliance with stringent fire safety standards essential for consumer electronics and industrial applications where fire hazards pose significant risks.

– Examples of Electronic Components Benefiting from EPO as a Flame Retardant

Electronic components such as circuit boards, connectors, and insulation materials derive substantial benefits from EPO’s flame retardant properties. By incorporating EPO into their composition, manufacturers enhance the fire resistance of these components, safeguarding against fire-related damage and ensuring continued operational safety in critical electronic systems.

– Comparative Advantages Over Other Flame Retardants in Electronic Applications

Compared to traditional flame retardants like brominated or chlorinated compounds, EPO offers distinct advantages. It serves as a less toxic alternative with superior environmental compatibility, addressing growing concerns over the ecological impact of chemical additives. Moreover, EPO’s usage does not compromise the electrical performance of electronic materials—a common issue with halogenated flame retardants—making it a preferred choice in high-performance electronic applications where reliability and safety are paramount.

Role as an Intermediate in Organic Synthesis

– Overview of Organic Synthesis Applications

Diphenyl(4-vinylbenzyl)phosphine oxide (EPO) serves as a crucial intermediate in organic synthesis, owing to its versatile chemical properties. It finds extensive applications in the synthesis of complex organic molecules across various industries. Chemists leverage EPO’s reactivity to enable selective transformations, essential in the development of pharmaceuticals, agrochemicals, and advanced materials where precise chemical control is paramount.

– Reactions Where EPO Serves as a Key Intermediate

EPO plays a pivotal role in diverse organic reactions, acting both as a catalyst and a reactant. Its involvement in radical polymerization reactions stands out, allowing for the synthesis of polymers with tailored properties critical for industrial applications. Additionally, EPO’s phosphine oxide group facilitates interactions with organometallic reagents, enabling the formation of intricate molecular structures crucial in medicinal chemistry and material science advancements.

– Importance of Purity and Synthesis Methods

The efficacy of EPO as an intermediate hinges on its purity and the rigor of synthesis methods employed. High purity levels ensure that subsequent reactions proceed efficiently, free from contaminants that could compromise product quality. Advanced synthesis techniques are indispensable for maintaining EPO’s chemical integrity, ensuring its reliability in sensitive chemical processes. Thus, stringent quality controls in EPO production are essential to uphold its efficacy in organic synthesis applications.

Environmental and Safety Considerations

– Environmental Impact and Regulations Concerning EPO Usage

The environmental impact of EPO usage, notably in flame retardants and organic synthesis, is closely regulated. Regulatory bodies mandate stringent oversight over its production, application, and disposal to mitigate environmental risks. Compliance with regulations governing emissions and chemical waste management is critical for manufacturers and users alike to ensure minimal environmental impact throughout the lifecycle of EPO.

– Safety Considerations During Handling and Processing

Due to its chemical reactivity and potential health hazards, safe handling and processing of EPO are imperative. Personnel involved in its handling should adhere to strict safety protocols, including the use of appropriate personal protective equipment (PPE) such as gloves, goggles, and adequate ventilation systems. Comprehensive training in emergency procedures is essential to mitigate risks associated with accidental exposure or spills.

– Disposal and Recycling Aspects

The disposal of EPO necessitates adherence to responsible waste management practices to minimize environmental impact. Proper disposal protocols should be followed, considering the potential for recycling EPO where feasible within industrial processes. Exploring recycling options aligns with sustainable practices, potentially reducing overall environmental footprint associated with EPO use in manufacturing and organic synthesis.

In Sum

Diphenyl(4-vinylbenzyl)phosphine oxide (EPO) proves to be highly versatile, finding crucial roles in flame retardancy for electronic materials and as a pivotal intermediate in organic synthesis, essential for creating intricate molecules across diverse industries. Its reactivity and compatibility with various polymers underscore its efficacy in enhancing product safety and performance. However, adherence to environmental regulations, stringent safety protocols during handling, and responsible disposal practices are imperative to mitigate associated risks. By integrating innovation with sustainable practices, EPO not only advances technology but also champions environmental stewardship in chemical applications.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs