Fire Safety Champion: Exploring Flame Retardant P-Xylylen-Bis-Diphenylphosphinoxid (CAS No. 38661-56-2)

P-Xylylen-Bis-Diphenylphosphinoxid (CAS No. 38661-56-2), commonly known as XDPO or DPOPD, stands out. This halogen-free, high-performance flame retardant, chemically named p-diphenyl bisdiphenyl phosphine oxide, boasts a structure similar to DOPO derivatives. Notable for its high melting point of 334 degrees and a decomposition temperature of 379 degrees, XDPO excels in heat resistance. Widely applied in the electronics sector and advanced materials, its applications extend to high-grade copper clad plates, various resins, and substrates used in 5G technology. XDPO’s versatility also allows it to serve as a photoinitiator and intermediate in organic synthesis, showcasing its pivotal role across diverse industries.

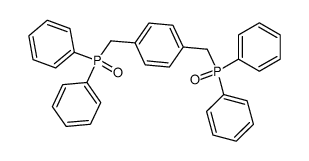

Chemical Structure and Properties

Chemical Composition and Molecular Structure of P-Xylylen-Bis-Diphenylphosphinoxid

P-Xylylen-Bis-Diphenylphosphinoxid (CAS No. 38661-56-2), also referred to as XDPO or DPOPD, features a molecular structure characterized by a central phosphorus atom bonded to two phenyl rings and an aromatic ring system. This specific arrangement is pivotal for its stability and flame-retardant capabilities, closely resembling other DOPO derivatives. The molecular configuration ensures XDPO maintains integrity and functionality even under high thermal stress, making it highly effective in diverse applications requiring fire resistance.

Physical and Chemical Properties Relevant to Its Effectiveness as a Flame Retardant

XDPO exhibits essential physical and chemical properties that bolster its efficacy as a flame retardant. With a high melting point of 334 degrees Celsius and a decomposition temperature of 379 degrees Celsius, XDPO showcases remarkable thermal stability, ensuring reliable performance in elevated temperature environments. Its high glass transition temperature (Tg) further enhances thermal resilience, crucial for materials exposed to heat. Additionally, XDPO’s low dielectric constant and minimal dielectric loss make it ideal for electronic materials, preserving electrical properties under stringent conditions. These attributes collectively enable XDPO to deliver robust flame retardancy while maintaining material integrity.

Comparison with Other Commonly Used Flame Retardants

Compared to conventional flame retardants, XDPO offers distinct advantages. Being halogen-free, XDPO mitigates the emission of toxic gases during combustion, unlike halogenated counterparts. Its chemical stability and superior thermal resistance outperform many traditional flame retardants, including phosphorus-based compounds like triphenyl phosphate (TPP) and tetrabromobisphenol A (TBBPA). Moreover, XDPO’s low thermal expansion rate and high glass transition temperature contribute to enhanced dimensional stability and mechanical performance at elevated temperatures, crucial for high-performance applications. These attributes position XDPO as a preferred choice across industries demanding stringent safety standards and reliable performance.

Mechanism of Action

How P-Xylylen-Bis-Diphenylphosphinoxid Functions as a Flame Retardant

P-Xylylen-Bis-Diphenylphosphinoxid operates primarily through a char-forming mechanism. When exposed to heat, XDPO undergoes decomposition, releasing phosphoric acid and phenol. These by-products catalyze the formation of a protective char layer on the material’s surface. This char layer acts as a barrier, reducing heat transfer and limiting the availability of flammable gases, thereby slowing down the combustion process. This mechanism effectively suppresses flame spread and shields underlying materials from further damage during fire incidents.

Explanation of Its Role in Preventing or Delaying Combustion

XDPO plays a critical role in fire safety by inhibiting combustion through multiple mechanisms. By facilitating the formation of a stable char layer, XDPO effectively insulates the material from heat and oxygen, crucial elements for combustion. This action not only delays ignition but also extends the critical time window for evacuation and fire containment efforts. XDPO’s exceptional thermal stability ensures the durability and effectiveness of the char layer even under extreme temperatures, providing sustained protection throughout the fire event.

Examples of Materials and Applications Where It Is Particularly Effective

XDPO finds widespread application across various materials and industries due to its robust flame-retardant properties. It is extensively utilized in electronics for high-grade copper-clad laminates (CCLs), epoxy resins, and flame-retardant composites such as FR4 and FCCL. The compound’s compatibility with 5G technology substrates underscores its relevance in advanced telecommunications infrastructure, where thermal stability and electrical insulation are paramount. In textiles, XDPO enhances flame retardancy without compromising material strength or aesthetic qualities, making it suitable for safety apparel and furnishings.

Features of P-Xylylen-Bis-Diphenylphosphinoxid from UniVOOK Chemical

- High Efficiency Flame Retardant: XDPO exhibits superior flame-retardant properties with minimal additive requirements, enhancing overall material safety and performance.

- Low Thermal Expansion Rate, High Heat Resistance: Maintains structural integrity at elevated temperatures, ensuring stability and safety in high-heat applications.

- High Glass Transition Temperature: Ideal for applications requiring thermal stability, preventing deformation and maintaining mechanical properties under heat stress.

- Low Dielectric Constant and Low Dielectric Loss: Crucial for maintaining consistent electrical performance in electronic components, making XDPO suitable for high-frequency applications.

Applications

Industrial Applications Across Different Sectors

P-Xylylen-Bis-Diphenylphosphinoxid (XDPO) finds widespread use across diverse sectors due to its robust flame-retardant properties. In electronics, it enhances the fire resistance of high-grade copper-clad laminates crucial for circuit boards. The textile industry employs XDPO in producing fire-resistant fabrics for safety gear and home furnishings, ensuring they endure high temperatures during fire incidents. Moreover, in construction, XDPO is added to materials like foams and insulation to meet stringent fire safety standards, safeguarding buildings from rapid fire spread.

Specific Products or Materials Where P-Xylylen-Bis-Diphenylphosphinoxid Is Used

XDPO is prominently featured in products requiring high thermal stability and electrical integrity. It serves as a key component in epoxy resins and polyamides used in electronic applications, providing flame retardancy while maintaining mechanical and electrical properties. Within textiles, XDPO integrates into fibers and fabrics needing substantial fire resistance without compromising comfort or fabric quality. Additionally, it plays a crucial role in flame-retardant composites used in aerospace and automotive sectors, protecting parts from high temperatures and potential fire hazards.

Benefits of Using This Flame Retardant in Various Applications

XDPO offers significant advantages in various applications, primarily enhancing fire safety by effectively forming a protective char layer. This layer helps maintain material integrity under fire conditions without compromising flexibility, durability, or aesthetic appearance. Its halogen-free composition and minimal environmental impact make XDPO a preferred choice for industries prioritizing safety and sustainability.

Safety and Environmental Considerations

Safety Profile: Toxicity, Handling Considerations, and Regulatory Status

XDPO is known for its low toxicity compared to traditional flame retardants, requiring standard safety protocols typical in industrial chemical handling. Compliance with major regulatory standards confirms its safety for widespread use, with ongoing assessments ensuring alignment with evolving global safety regulations.

Environmental Impact and Sustainability Aspects

An advantageous attribute of XDPO is its minimal environmental impact as a halogen-free compound, avoiding the release of harmful halogenated compounds during production or combustion. Its stability prevents degradation into harmful by-products, reducing environmental footprint and aligning with sustainability goals across industries.

Comparison with Other Flame Retardants in Terms of Safety and Environmental Impact

Compared to halogenated flame retardants, which can emit toxic gases and persistent pollutants, XDPO offers a safer, more environmentally friendly alternative. Its chemical stability and halogen-free nature contribute to lower toxicity and reduced environmental degradation, positioning XDPO as a sustainable solution in flame retardant applications.

Future Trends and Research

Emerging Trends in Flame Retardant Technology

Future trends in flame retardant technology focus on developing safer, more efficient, and environmentally friendly compounds. Innovations aim to reduce volatility, minimize toxic by-products, and enhance compatibility across diverse materials without compromising performance. There is also growing interest in naturally derived flame retardants, reflecting a broader shift towards sustainable material solutions.

Ongoing Research and Development Related to P-Xylylen-Bis-Diphenylphosphinoxid

Current research endeavors seek to expand XDPO’s efficacy and application scope. Studies explore molecular modifications to optimize operational temperatures and enhance compatibility with heat-sensitive materials. Additionally, ongoing efforts aim to improve manufacturability, making XDPO more cost-effective and sustainable for broader industrial applications.

Potential Advancements or Improvements in Its Application and Safety

Future advancements in XDPO focus on refining formulations to boost flame-retardant properties while mitigating potential health risks. Innovations may include developing derivatives that offer superior smoke suppression and reduced toxicity. Continued research aims to enhance safety profiles and environmental compatibility, ensuring XDPO remains a reliable choice for advancing fire safety standards globally.

Closing Words

P-Xylylen-Bis-Diphenylphosphinoxid (XDPO) stands out as a highly effective flame retardant that enhances fire safety across diverse industrial sectors. Its proven performance in electronics, textiles, and construction underscores its versatility and reliability. XDPO not only meets rigorous fire safety standards but also supports environmental sustainability objectives with its halogen-free composition and low toxicity. Ongoing research aims to further optimize its applications, ensuring XDPO remains a forefront choice in flame retardant technology. As industries increasingly prioritize safety and sustainability, XDPO offers a dependable and eco-friendly solution to mitigate fire risks effectively.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs