Flame Retardant Tris(Trimethylsilyl) Phosphate(CAS No. 10497-05-9): Properties and Applications

Flame Retardant Tris(Trimethylsilyl) Phosphate (TMSP), identified by CAS number 10497-05-9, is a specialized chemical manufactured by UniVOOK Chemical, highly valued for its versatile applications. Predominantly utilized in electronics and textiles, TMSP effectively mitigates fire risks by reducing flammability in materials. It also serves as a pivotal intermediate in organic synthesis, facilitating the production of intricate chemical compounds. The significance of TMSP and similar flame retardants lies in their essential role in upholding stringent safety standards, safeguarding lives, and protecting property in environments vulnerable to fire hazards.

Applications of TMSP

Electronic Materials

Tris(Trimethylsilyl) Phosphate (TMSP) is indispensable in the manufacturing of electronic materials, where stringent safety standards demand robust fire resistance. As electronic devices evolve to be more compact and powerful, TMSP is integrated into components like circuit boards, casings, and insulation materials. Its primary role is enhancing fire retardant properties, effectively mitigating fire risks in devices prone to overheating or electrical failures.

Use of TMSP in Electronic Components and Devices

Within the electronics sector, TMSP finds extensive application in critical components such as servers, chargers, and power adapters. These components are susceptible to high temperatures and potential fire hazards. By incorporating TMSP, manufacturers bolster fire safety measures, significantly lowering the incidence of fire-related accidents and ensuring device reliability.

Benefits of TMSP in Improving Fire Safety in Electronic Applications

TMSP’s inclusion in electronic materials offers substantial benefits by elevating fire safety standards. It raises the ignition threshold of materials and retards the rate of combustion, providing valuable time for response during emergencies. This proactive approach not only safeguards equipment integrity but also protects lives and property from fire hazards.

Textile Industry (Spinning)

Role of TMSP in Flame Retardant Textiles

In the textile industry, TMSP plays a pivotal role in imparting flame retardant properties to fabrics. During the spinning process, TMSP is applied to both natural and synthetic fibers, enhancing their resistance to ignition and combustion. This application is crucial in textiles used across various sectors, including curtains, upholstery, and industrial protective clothing, where fire safety is paramount.

How TMSP Enhances the Fire Resistance of Textiles

The integration of TMSP into fiber manufacturing processes results in textiles with superior fire resistance characteristics. TMSP-treated fibers exhibit reduced flammability and quicker self-extinguishing properties compared to untreated materials. This inherent fire resistance is particularly valuable in demanding environments such as automotive and aerospace industries, where safety standards mandate stringent fire protection measures.

Chemical Properties of TMSP

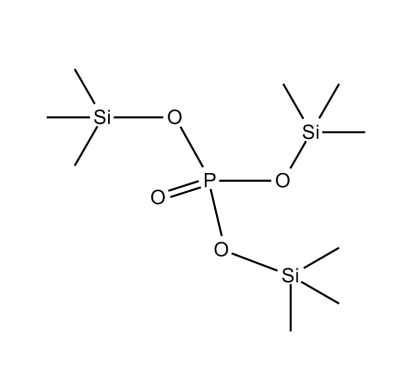

Molecular Structure and Composition

TMSP boasts a distinctive molecular structure featuring a phosphate core adorned with three trimethylsilyl groups. This configuration is instrumental in its efficacy as a flame retardant. The presence of silicon within its structure contributes to the formation of a protective barrier when exposed to heat, effectively impeding the combustion process.

Physical Properties Relevant to Its Applications

TMSP exhibits essential physical properties that enhance its suitability for high-temperature applications. Notably, its thermal stability and low volatility ensure sustained performance under extreme conditions where other flame retardants may degrade. These attributes make TMSP a preferred choice for industries requiring reliable fire protection solutions.

Synthesis of TMSP

Overview of the Synthetic Process

The synthesis of TMSP involves a meticulous series of chemical reactions initiated by the reaction between trimethylsilanol and phosphorus oxychloride. Control over reaction parameters such as temperature and pH is critical to achieving the desired purity and yield of TMSP, essential for its effective application in diverse industrial settings.

Key Intermediates and Reaction Mechanisms Involved

Throughout its synthesis, TMSP undergoes transformations via intermediates like trimethylsilyl dihydrogen phosphate. These intermediates participate in further reactions, including nucleophilic substitution and silylation processes, ultimately culminating in the formation of TMSP. Understanding these intricate mechanisms is pivotal for optimizing synthesis protocols, enhancing yield efficiency, and minimizing production costs of TMSP.

Environmental and Safety Considerations

Environmental Impact of TMSP

Tris(Trimethylsilyl) Phosphate (TMSP) is widely used in industries requiring flame retardant materials, posing environmental challenges due to its persistence and potential for bioaccumulation. While TMSP effectively enhances fire safety, ongoing studies are crucial for understanding its degradation pathways and long-term effects on ecosystems. Balancing the benefits of fire safety with environmental sustainability is paramount in its continued use.

Safety Protocols in Handling and Manufacturing TMSP

Safe handling and manufacturing of TMSP necessitate stringent protocols to safeguard workers and prevent environmental harm. Facilities must enforce adequate ventilation, provide protective gear, and conduct thorough staff training. Emergency response plans are essential to manage spills or exposures, minimizing risks associated with TMSP’s volatile and reactive nature.

Future Trends and Developments

Advancements in TMSP Applications

Research into TMSP applications is expanding to improve its efficacy and environmental profile. Innovations focus on developing formulations that reduce TMSP usage while maintaining fire retardancy. Efforts also include integrating TMSP into recyclable and biodegradable materials, aligning with stringent environmental and safety regulations without compromising performance.

Future Technological Enhancements in TMSP

The future of TMSP technology holds promise with advancements aimed at reducing environmental impact and enhancing application efficiency. Scientists are exploring biodegradable alternatives and refining synthesis methods to minimize waste and energy consumption. Additionally, advancements in nanotechnology offer opportunities to optimize TMSP deployment in diverse materials, boosting fire resistance while minimizing environmental footprint.

Final Words

Tris(Trimethylsilyl) Phosphate (TMSP) plays a crucial role in manufacturing flame-retardant materials essential across diverse industries, notably electronics and textiles. Its unique molecular structure and physical properties effectively enhance fire safety in modern manufacturing applications. However, addressing TMSP’s environmental impact and safety concerns requires diligent management and ongoing research. Innovations are underway to develop sustainable TMSP formulations, minimize environmental footprint, and integrate it into biodegradable materials. Looking ahead, advancements in TMSP technology hold promise for enhancing application efficiency while mitigating environmental effects. Achieving a balance between TMSP’s fire safety benefits and its ecological impact is pivotal for its sustainable use in industrial applications.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs