The Role of CPL Antioxidants in Plastic and Rubber Industries

Antioxidants are pivotal in the plastic and rubber industries, shielding materials from degradation and prolonging their lifespan. They counteract oxidative stress triggered by heat, light, and oxygen exposure, thereby preserving product integrity and performance. Specifically, CPL antioxidants are indispensable for bolstering the durability and stability of plastics and rubbers. UniVOOK Chemical, China’s leading manufacturer and supplier of antioxidants, offers top-tier CPL antioxidants(CAS No. 68610-51-5) tailored for both natural and synthetic materials such as SBR, NBR, latex, ABS, SBS, and SIS. These antioxidants guarantee enduring performance and resilience across diverse applications.

Understanding CPL Antioxidants

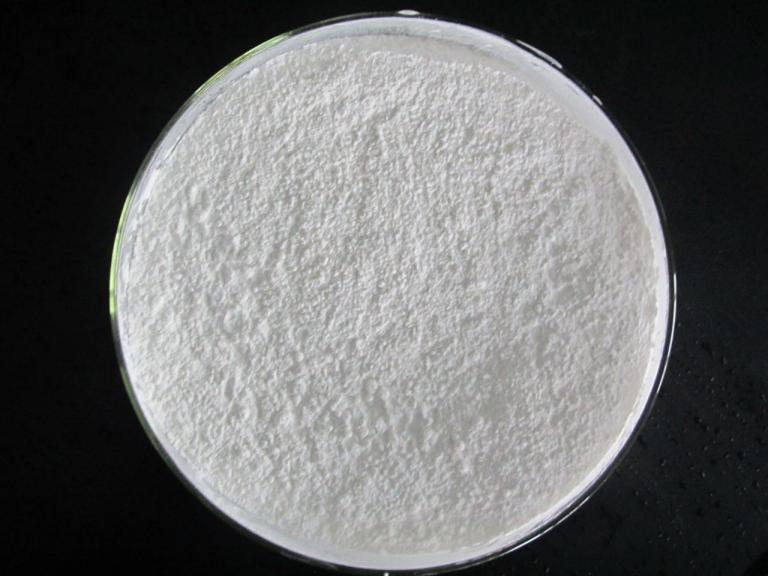

Explanation of CPL Antioxidants

Antioxidant CPL is a flaky solid, ranging from colorless to light yellow. This polymeric hindered phenolic antioxidant is known for its excellent compatibility, minimal volatility, effective dispersion, low migration tendencies, and robust thermal stability. It demonstrates high antioxidant efficiency, particularly in resisting elevated temperatures, deterring extraction, impeding migration, and maintaining resilience against hydrolysis. These qualities make CPL antioxidants essential in various industrial applications where long-lasting material performance is critical.

Types of CPL Antioxidants and Their Chemical Properties

CPL antioxidants come in different types, each with unique chemical properties tailored to specific applications. These types include primary antioxidants, which intercept free radicals to prevent oxidation, and secondary antioxidants, which decompose hydroperoxides into non-radical products. The chemical properties of CPL antioxidants ensure they provide comprehensive protection against oxidative degradation, enhancing the stability and longevity of plastic and rubber products.

Importance of Antioxidants in Plastics and Rubber

Protection Against Oxidation and Degradation

Antioxidants are crucial in protecting plastics and rubber from oxidation and degradation. Exposure to heat, light, and oxygen can cause these materials to deteriorate, leading to loss of physical properties, discoloration, and reduced mechanical strength. By neutralizing free radicals and decomposing peroxides, antioxidants prevent the oxidative breakdown of polymers, thereby preserving their structural integrity and appearance.

Role in Extending Product Lifespan and Durability

The use of antioxidants significantly extends the lifespan and durability of plastic and rubber products. By preventing oxidative damage, antioxidants help maintain the mechanical properties and aesthetic qualities of these materials over time. This leads to longer-lasting products that can withstand harsh environmental conditions, ultimately offering better value and performance to end-users.

Functions of CPL Antioxidants

Mechanisms of Action in Plastic and Rubber Materials

CPL antioxidants are non-staining and non-discoloring phenolic compounds that excel in protecting light-colored polymers such as natural and synthetic rubber, latex, and ABS. Their low volatility makes them ideal for stabilizing materials used in everyday items like elastic threads, carpet backing, foam mattresses, and baby bottle teats. Additionally, CPL antioxidants shield ABS, SBS, and SIS plastics, fortifying automotive components, household goods, and electronic devices. From the bounce in basketballs to the shine on shoes, CPL antioxidants play a vital role in maintaining the performance and durability of everyday products.

Specific Benefits in Different Applications

CPL antioxidants offer specific benefits across various applications. In the automotive industry, they enhance the durability and performance of components exposed to high temperatures and harsh environmental conditions. In packaging, CPL antioxidants prevent the degradation of plastics, ensuring the safety and longevity of packaged goods. Their role extends to consumer electronics, where they help maintain the functionality and appearance of devices. By providing reliable protection against oxidative damage, CPL antioxidants are indispensable in numerous industrial and consumer applications, ensuring products remain safe, durable, and efficient.

Applications in the Industry

Versatility in Latex Products

Antioxidant CPL is essential across a wide array of latex products, demonstrating its versatility in both household and medical applications. It forms stable emulsions and serves as a standard antioxidant in latex-based items such as gloves, condoms, latex foam, rings, carpet adhesives, medical products, baby pacifiers, bath mats, hot water bottles, paper coatings, and various daily use latex products. Its effectiveness extends to natural latex used in automotive and electronic accessories, including formulations like styrene-butadiene and carboxystyrene-butadiene.

Enhancing Rubber Product Durability

Antioxidant CPL plays a crucial role in safeguarding against discoloration and premature embrittlement in diverse rubber products. It significantly boosts the resilience and tensile strength of rubber, encompassing various types such as natural rubber (NR), nitrile rubber (NBR), butadiene rubber (BR), ethylene propylene diene monomer (EPDM), styrene-butadiene rubber (SBS), styrene-isoprene-styrene (SIS), and other elastomers. This makes it indispensable for maintaining the durability and performance of rubber used extensively in industrial and consumer applications.

Stability in Thermoplastic Styrene Copolymers

Tailored for thermoplastic styrene copolymers such as acrylonitrile butadiene styrene (ABS) and methyl methacrylate butadiene styrene (MBS), Antioxidant CPL delivers enduring and stable antioxidant effects throughout the synthesis process. Its synergistic benefits are particularly notable when combined with auxiliary antioxidants like phosphites and thioester antioxidants. This synergistic approach ensures enhanced stability and performance of styrene copolymers utilized in various manufacturing processes.

Advantages in Polyamide Resins and Thermoplastics

Antioxidant CPL offers distinct advantages in applications involving polyamide resins, particularly PA6 and PA. Its effectiveness also extends to a range of thermoplastics, including polypropylene (PP) and polyethylene (PE). Additionally, it finds application in hot melt adhesives, adhesives, and lubricants, providing a reliable and robust antioxidant solution compared to conventional alternatives. This broad applicability positions it as a preferred choice in diverse industrial settings, ensuring longevity and optimal performance of materials.

Future Trends and Innovations

Emerging Technologies and Advancements in CPL Antioxidants

The field of CPL antioxidants is poised for significant advancements with emerging technologies focusing on enhancing efficacy and environmental compatibility. Innovations are aimed at developing more sustainable and efficient antioxidant solutions that offer superior protection against oxidative stress. Researchers are exploring novel formulations and manufacturing techniques to further enhance the performance and expand the application scope of CPL antioxidants.

Predictions for Future Developments in the Field

Future developments in CPL antioxidants are expected to concentrate on creating multifunctional additives that provide comprehensive protection and improved material properties. These advancements will likely involve integrating CPL antioxidants with other stabilizers and performance enhancers to meet the evolving demands across various industries. With sustainability becoming increasingly critical, the industry is likely to witness the development of eco-friendly CPL antioxidants that minimize environmental impact while maintaining high performance standards.

In Sum

Antioxidants play a critical role in the plastic and rubber industries by protecting materials from degradation and extending their lifespan. They neutralize oxidative stress caused by exposure to heat, light, and oxygen, thereby preserving the integrity and performance of products. CPL antioxidants, specifically designed by UniVOOK Chemical, China’s foremost manufacturer and supplier in this field, enhance the durability and stability of plastics and rubbers like SBR, NBR, latex, ABS, SBS, and SIS. These advanced antioxidants ensure long-lasting performance and resilience across a wide range of applications, maintaining the safety, durability, and efficiency of products. As technology advances, the future of CPL antioxidants holds promise for even greater innovation and sustainability within the industry.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs