Preserving Quality: The Role of DLTDP as a Plastic and Rubber Antioxidant

Antioxidants are essential for prolonging the lifespan and durability of plastics and rubber products by preventing oxidative degradation. Dilauryl Thiodipropionate (DLTDP) (CAS No. 123-28-4), a thioester, plays a pivotal role as a stabilizer in these industries. Widely utilized alongside phenolic antioxidants, DLTDP effectively shields materials like polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), high-impact polystyrene, ABS resin, natural rubber, synthetic rubber, and grease from the detrimental effects of oxidation.

Understanding Antioxidants in Plastic and Rubber

Importance of Antioxidants in Preserving Product Quality

Antioxidants play a critical role in maintaining the quality and durability of plastic and rubber products. They prevent oxidative degradation, which can lead to brittleness, discoloration, and loss of mechanical properties over time. By incorporating antioxidants, manufacturers ensure that their products retain desired characteristics such as flexibility, strength, and appearance, even when exposed to environmental stressors like heat, light, and oxygen.

Common Challenges Without Antioxidant Protection

Without antioxidant protection, plastic and rubber products face significant challenges. Oxidation can cause deterioration, impacting the material’s performance and lifespan. Issues include color fading, surface cracking, loss of elasticity, and overall weakening of structural integrity. These problems not only compromise product functionality but also increase maintenance costs and pose potential safety risks. In industrial settings, such issues can result in costly downtime and the need for frequent replacements.

DLTDP: Properties and Mechanism of Action

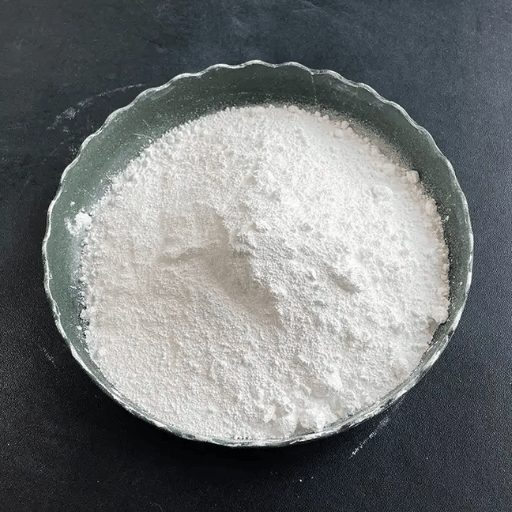

Chemical Structure and Properties of DLTDP

Dilauryl Thiodipropionate (DLTDP) is a thioester known for its unique chemical structure that makes it highly effective as an antioxidant. This structure enables DLTDP to interact with free radicals and peroxides, key agents of oxidative degradation. High thermal stability and compatibility with a wide range of polymers enhance its suitability for enhancing the longevity of plastic and rubber products.

How DLTDP Prevents Oxidation in Plastics and Rubber

DLTDP functions by scavenging free radicals and decomposing peroxides generated during oxidative degradation. By disrupting oxidation chain reactions, DLTDP helps preserve the molecular structure of polymers, thereby maintaining their physical and mechanical properties. This ensures that products retain their performance and reliability under challenging environmental conditions.

Comparison with Other Antioxidants in the Market

DLTDP offers distinct advantages compared to other antioxidants. It exhibits high compatibility with various polymers such as polypropylene, polyethylene, PVC, and ABS resin. While phenolic antioxidants are effective, DLTDP provides enhanced protection, particularly in combination with these compounds. Its exceptional thermal stability makes it particularly suitable for applications involving prolonged exposure to high temperatures, distinguishing it as a preferred choice for comprehensive oxidative protection.

Oxidative Protection

DLTDP’s primary function is to shield materials like polymers, plastics, and rubber from oxidative degradation by neutralizing free radicals and decomposing peroxides, crucial contributors to material deterioration.

Extended Shelf Life

By mitigating oxidation’s harmful effects, DLTDP extends the shelf life of treated materials, ensuring sustained performance and durability over prolonged periods, crucial for maintaining product integrity.

Heat Stability

DLTDP excels in environments with elevated temperatures, providing reliable heat stability and safeguarding against thermal degradation. This capability is essential for preserving material integrity in high-heat applications.

Preservation of Structural Integrity

DLTDP’s stabilizing properties uphold the structural integrity of industrial materials, promoting durability and reducing the risk of premature failure. This reliability is vital for maintaining product performance in demanding applications.

Applications of DLTDP

Polymer Industry

DLTDP plays a crucial role in the polymer industry, safeguarding against thermal and oxidative degradation. By inhibiting oxidation, DLTDP extends the service life of polymers like polypropylene (PP) and polyethylene (PE). This antioxidant preserves the structural integrity and performance of these materials, enhancing their durability and reliability for diverse applications.

Plastics Industry

In the plastics industry, DLTDP protects materials from the harmful effects of heat and oxygen. Widely applied in polyvinyl chloride (PVC), high-impact polystyrene, and ABS resin, DLTDP prevents issues such as brittleness and discoloration. UniVOOK Chemical’s DLTDP antioxidant excels in these conditions, ensuring plastics maintain their strength and desired properties over extended periods.

Rubber Industry

DLTDP significantly enhances the longevity and strength of natural and synthetic rubber products in the rubber industry. By providing advanced protection against oxidative processes, DLTDP preserves the elasticity and performance of rubber materials. This makes it indispensable for applications requiring resilience in challenging environments, ensuring consistent performance over time.

UniVOOK Chemical’s antioxidant DLTDP offers reliable solutions to enhance material durability and extend service life across diverse industrial applications. Choose UniVOOK Chemical for superior protection and stability in your operations.

Benefits of Using DLTDP

Enhanced Product Lifespan and Durability

DLTDP significantly enhances the lifespan and durability of plastic and rubber products by effectively inhibiting oxidative degradation. This antioxidant preserves the structural integrity and mechanical properties of materials over time, ensuring they can withstand harsh environmental conditions such as heat, light, and oxygen exposure without degradation. Manufacturers can thereby deliver high-quality, long-lasting products that maintain reliability and performance throughout their lifecycle.

Cost-Effectiveness in Production Processes

Incorporating DLTDP into production processes proves cost-effective for manufacturers by extending the service life of materials. This reduces the frequency of replacements and maintenance, lowering overall production costs. Enhanced material durability also decreases the occurrence of product failures and returns, saving additional costs associated with warranty claims and customer service. Moreover, DLTDP optimization enhances production efficiency by minimizing downtime and prolonging the lifespan of processing machinery and equipment.

Environmental and Health Safety Considerations

DLTDP offers environmental and health safety benefits as a stabilizer in plastics and rubber. By minimizing the release of harmful degradation products into the environment, it contributes to a reduced environmental footprint. Compliant with stringent safety regulations, DLTDP poses minimal health risks to workers and end-users. Its effective stabilization properties enable products to achieve longer lifespans, reducing waste and the need for raw materials. Manufacturers opting for DLTDP can align with sustainable practices, promoting a safer working environment while enhancing product sustainability.

Challenges and Future Trends

Challenges Faced in the Use of DLTDP

Despite its benefits, the use of DLTDP presents challenges, including compatibility issues with different polymers and formulations that may affect its efficacy in various applications. Higher costs compared to some alternative antioxidants can impact production budgets, requiring manufacturers to carefully assess economic feasibility. Adapting to evolving regulatory standards and addressing environmental concerns necessitates ongoing adjustments to formulations and processes to maintain compliance and sustainability.

Emerging Trends in Antioxidant Technologies for Plastics and Rubber

Future trends in antioxidant technologies for plastics and rubber are characterized by ongoing innovation. Multifunctional antioxidants that combine DLTDP with other stabilizers are being developed to enhance overall performance and efficacy. There is also a growing emphasis on bio-based and environmentally friendly antioxidants to address sustainability challenges. Advances in nanotechnology are driving the development of more efficient and targeted antioxidant solutions, offering enhanced protection at reduced concentrations. Manufacturers are increasingly adopting these cutting-edge technologies to meet rising demands for high-performance, sustainable materials, thereby driving industry evolution towards a more sustainable future.

Closing Words

Antioxidants play a crucial role in extending the lifespan and durability of plastics and rubber products by preventing oxidative degradation. Dilauryl Thiodipropionate (DLTDP) (CAS No. 123-28-4), a thioester, is a key stabilizer widely used in these industries. When combined with phenolic antioxidants, DLTDP effectively protects materials such as polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), high-impact polystyrene, ABS resin, natural rubber, synthetic rubber, and grease from the damaging effects of oxidation. Integrating DLTDP into manufacturing processes not only enhances product quality and prolongs material lifespan but also promotes environmental sustainability by reducing waste and resource consumption. By embracing DLTDP’s benefits and keeping pace with advancements in antioxidant technologies, manufacturers can ensure the ongoing advancement of robust, eco-friendly plastic and rubber products across diverse industrial applications.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs