TMAH Developer for Semiconductor Industry

TMAH, Tetramethylammonium Hydroxide, plays a pivotal role in semiconductor manufacturing, primarily in photolithography processes. As a developer, it facilitates the creation of precise patterns on silicon wafers, crucial for manufacturing integrated circuits and various electronic devices. This compound’s significance lies in its ability to etch these intricate patterns accurately and efficiently, ensuring the production of high-quality semiconductor components. TMAH’s widespread use underscores its importance in advancing technology, enabling the fabrication of increasingly complex and compact electronic devices essential for modern industries and everyday life.

Understanding TMAH

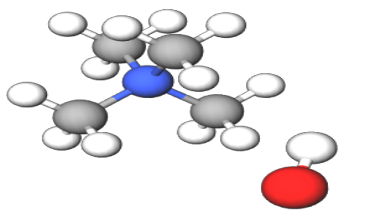

Chemical Properties and Structure of TMAH

Tetramethylammonium Hydroxide (TMAH) is a quaternary ammonium compound typically presented in aqueous solutions or as a white crystalline solid. Structurally, TMAH consists of four methyl groups attached to a nitrogen atom, making it a strong base. It is highly soluble in water, with a strong alkaline nature, which makes it effective in various chemical processes.

Applications in the Semiconductor Industry

In semiconductor manufacturing, TMAH finds its primary use in photolithography—a critical step where it serves as a positive photoresist developer. By breaking down the exposed photoresist areas, TMAH helps in transferring intricate circuit patterns from a mask to the silicon wafer, enabling subsequent etching and layering processes vital for integrated circuit fabrication.

Safety Considerations and Handling Procedures

Handling TMAH requires strict safety precautions due to its highly corrosive nature and potential health hazards. It can cause severe skin burns and eye damage upon contact, and its fumes are harmful if inhaled. Therefore, appropriate protective gear, such as gloves, goggles, and respirators, must be worn. Additionally, facilities using TMAH must ensure proper ventilation and have emergency wash stations readily accessible to mitigate any accidental exposure.

Development Process

Research and Analysis of Current TMAH Formulations

The ongoing development of TMAH formulations involves analyzing the chemical stability, efficacy in photoresist development, and potential environmental impacts. Research aims to enhance the performance of TMAH in semiconductor processes while reducing its corrosivity and toxicity.

Identification of Requirements and Specifications for Semiconductor Manufacturing

The specific needs for semiconductor manufacturing guide the development of specialized formulations. UniVOOK Chemical’s TMAH Developer is designed with a precise 2.38% TMAH concentration, optimized for detailed pattern creation on semiconductor substrates while safeguarding the delicate metal layers involved.

Features: TMAH Developer

- TMAH Content: The developer’s 2.38% concentration is crucial for efficiently removing specific regions of photoresist, facilitating the accurate etching required for circuit formation.

- Unique Metal Protective Agent: This agent protects the critical metal layers from potential chemical damage during development, ensuring the structural and electrical integrity of the semiconductor devices.

- Protective Function: The metal protective agent ensures selective etching by safeguarding non-targeted areas, crucial for maintaining device functionality.

- Substrate Protection: By preventing substrate damage, this formulation enhances the reliability and yield of semiconductor manufacturing processes.

- Precision in Pattern Formation: The precise interaction between TMAH and the protective agent enables the formation of complex patterns essential for modern integrated circuits.

Optimization of TMAH Formulation for Specific Semiconductor Processes

Adjusting the TMAH concentration and the composition of protective agents is critical for tailoring the developer to meet specific manufacturing demands. This optimization process involves extensive testing and iterative refinement to balance development speed with pattern fidelity.

Testing for Compatibility, Purity, and Efficacy

Before full-scale implementation, the TMAH developer undergoes rigorous testing to ensure compatibility with different photoresist types, purity levels sufficient to prevent circuit defects, and overall efficacy in pattern development. These tests are essential to confirm that the TMAH developer meets all specifications for high-performance semiconductor manufacturing.

Quality Control and Assurance

Establishing Quality Control Measures for TMAH Production

UniVOOK Chemical employs stringent quality control measures to ensure the reliability and efficacy of its TMAH Developer. This starts from the meticulous monitoring of chemical synthesis to final product testing. The production process incorporates several checkpoints to assess the chemical concentration, purity, and consistency, ensuring that each batch meets the high standards required for semiconductor manufacturing.

Regular Testing and Analysis for Purity, Stability, and Performance

Regular testing is a cornerstone of UniVOOK Chemical’s quality assurance program. Each batch of TMAH Developer undergoes rigorous testing for purity, to prevent any impurities that could affect semiconductor manufacturing. Stability tests ensure that the developer maintains its performance over time under various storage conditions. Performance testing, on the other hand, confirms that the developer meets all operational requirements for photolithography processes.

Documentation and Record-Keeping Procedures

Documentation and meticulous record-keeping are crucial for maintaining high standards of quality and for traceability in production. UniVOOK Chemical maintains comprehensive records of each production batch, including details of raw materials, production conditions, test results, and handling procedures. These records are essential not only for internal quality audits but also for complying with industry regulations and standards.

Supply Chain Management

Sourcing Raw Materials for TMAH Production

UniVOOK Chemical strategically sources high-quality raw materials to ensure the production of superior TMAH Developer. The sourcing process involves rigorous assessment of suppliers to guarantee that the raw materials meet stringent quality standards essential for the production of high-grade chemical developers.

Establishing Partnerships with Suppliers

Over the past 16 years, UniVOOK Chemical has built strong relationships with key suppliers. This has been achieved by investing in partnerships that enhance the supply chain’s reliability and efficiency. These collaborations involve not just the procurement of raw materials, but also the integration of advanced third-party R&D labs, production plants, and cutting-edge technology. Such partnerships enable UniVOOK Chemical to adapt to evolving market demands and maintain a competitive edge in the specialty chemicals and advanced materials industry.

Logistics and Distribution Considerations

The logistics and distribution strategy of UniVOOK Chemical ensures timely and safe delivery of the TMAH Developer to semiconductor manufacturers worldwide. This includes choosing optimal transportation methods, managing warehousing conditions to preserve chemical integrity, and implementing tracking systems to monitor shipments, thus ensuring that the developer reaches production facilities in pristine condition.

Future Trends and Innovations

Emerging Technologies and Advancements in Semiconductor Manufacturing

The semiconductor industry is rapidly evolving with the introduction of new fabrication technologies and materials. Advancements such as extreme ultraviolet lithography (EUV) are pushing the boundaries of what’s possible, necessitating the development of new chemical formulations, including TMAH Developers, that are compatible with these advancements.

Potential Improvements or Innovations in TMAH Formulations

Looking ahead, UniVOOK Chemical is focused on improving the environmental profile and operational efficiency of its TMAH solutions. Innovations may include formulations that offer lower toxicity and greater biodegradability without compromising performance, addressing both environmental concerns and regulatory pressures.

Anticipated Challenges and Opportunities in the Industry

The semiconductor industry faces challenges such as raw material scarcity, stringent environmental regulations, and the need for continual technological advancements. However, these challenges also present opportunities for UniVOOK Chemical to innovate and develop solutions that meet these emerging needs. The company is well-positioned to leverage its expertise in chemical development to create products that not only meet current industry standards but also set new benchmarks for quality and sustainability in the semiconductor sector.

Final Words

The TMAH Developer provided by UniVOOK Chemical stands as a fundamental element in semiconductor manufacturing. Through meticulous formulation and rigorous quality control, it guarantees not just the precise creation of complex patterns but also safeguards crucial underlying metal structures. As the semiconductor industry progresses, the evolution of TMAH formulations and adept supply chain management will be instrumental in meeting shifting industry needs, tackling obstacles, and seizing opportunities for sustainability and performance enhancement. UniVOOK Chemical remains steadfast in its dedication to spearheading these advancements and furnishing state-of-the-art solutions to semiconductor manufacturers globally.

Access Our Product Catalog and More to Discover High-Performance Chemicals Tailored to Your Business Needs